Fire

Fishing vessel Fundy Leader

100 nautical miles southwest of Cape Sable, Nova Scotia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Description of the vessel

The Fundy Leader (Transport Canada official number 828432) is a fishing vessel with a registered length of 32.13 m and a gross tonnage of 419 (Figure 1). The vessel was built in 2005 as a trawler but underwent a major conversion in 2015 to fish scallops. The vessel is owned by Clearwater Seafoods, which owns and operates 20 other vessels.

The vessel is of a double deck design with the accommodations and wheelhouse located forward of amidships. The processing area is aft on the main deck. The area below the main deck is divided into 4 compartments (from forward): the forepeak, the engine room, the fish hold, and the aft peak. The hull is constructed of steel.

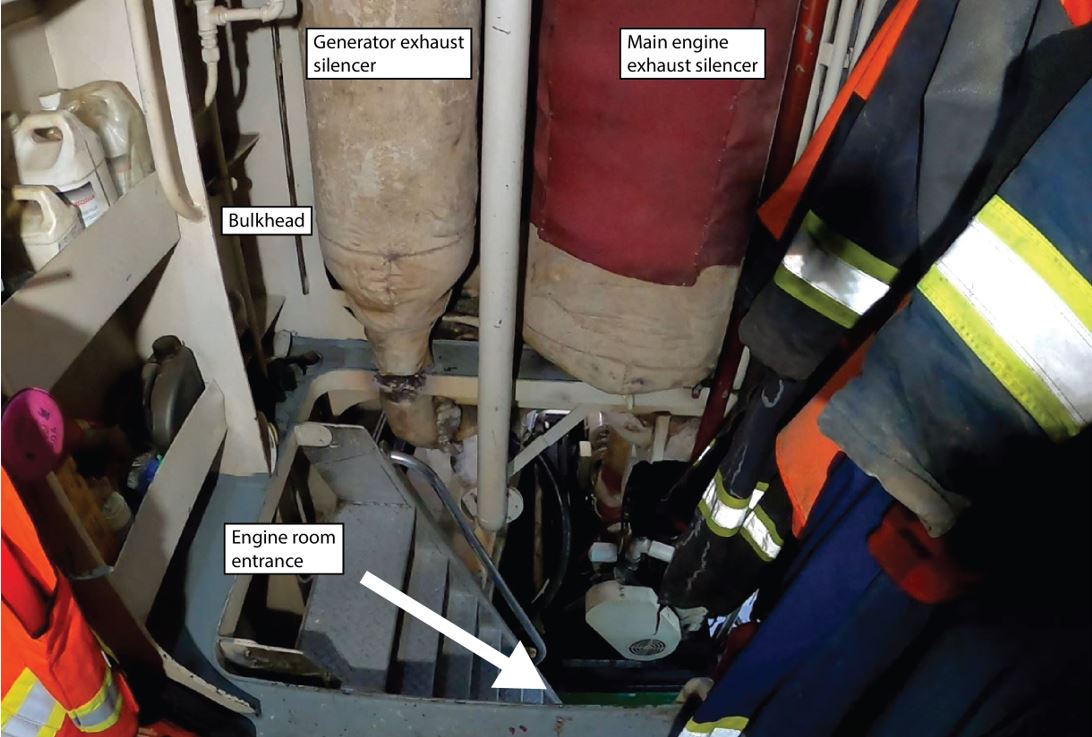

The exhaust trunking, which contains the exhaust pipes for the vessel’s main engine and 3 generators, is directly aft of the accommodations.On fishing vessels, it is common for the exhaust trunking to either pass through the accommodations or be directly aft of it. The exhaust trunking on the Fundy Leader is accessed from the engine room entrance on the main deck. The exhaust pipe for the main engine is located in the forward part of the exhaust trunking.

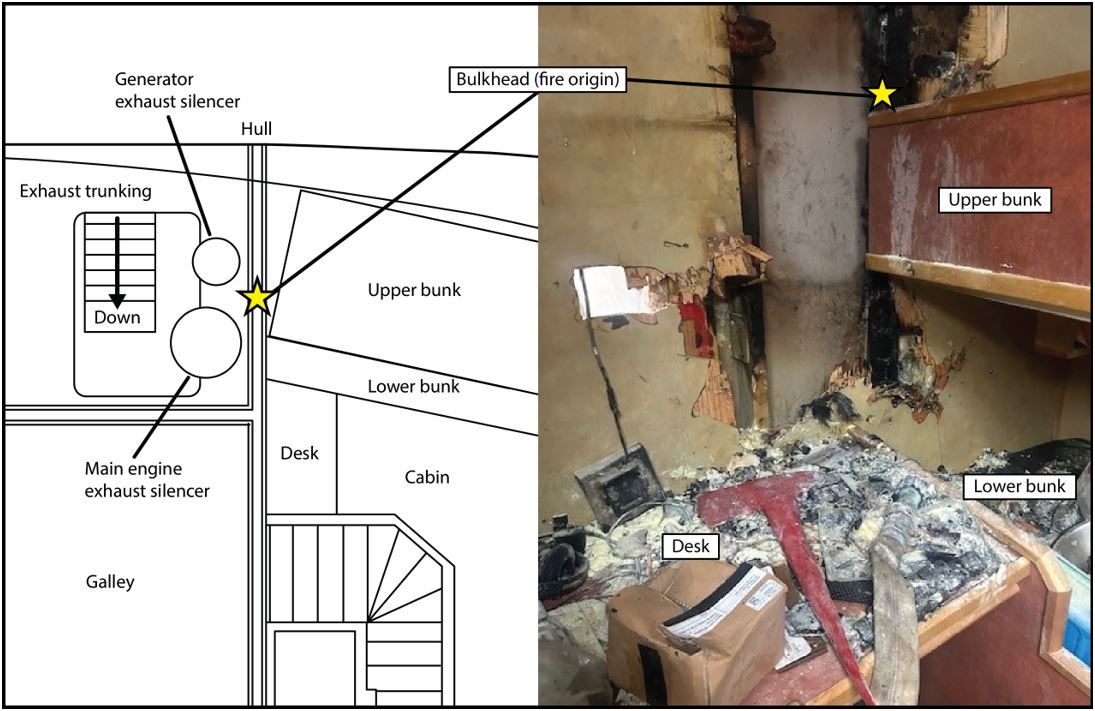

The main engine exhaust pipe is fitted with an exhaust silencer, which is essentially a muffler designed to reduce the noise of the main engine. The silencer is cylindrical in shape and is larger in circumference than the rest of the pipe. It is fitted into a section of the pipe using flanges. The exhaust pipe and silencer are covered with non-combustible thermal insulation (lagging) that reduces the transfer of heat to the surrounding area and prevents people and objects from making contact with the hot pipe.Section 13(5) of the Large Fishing Vessel Inspection Regulations (C.R.C., c. 1435) requires that exhaust pipes and silencers be “efficiently water-cooled, lagged or so installed that they will create no fire hazard.” On the Fundy Leader, the main engine exhaust silencer is within 10 cm of the steel bulkhead that separates the exhaust trunking from the accommodations (Figure 2).

The Fundy Leader carries 12 portable fire extinguishers of varying sizes and types. The engine room is equipped with a carbon dioxide fixed fire suppression system. There are also a fire pump and hoses, 2 firefighting suits, 2 self-contained breathing apparatuses, and 3 spare air cylinders on board.

History of the voyage

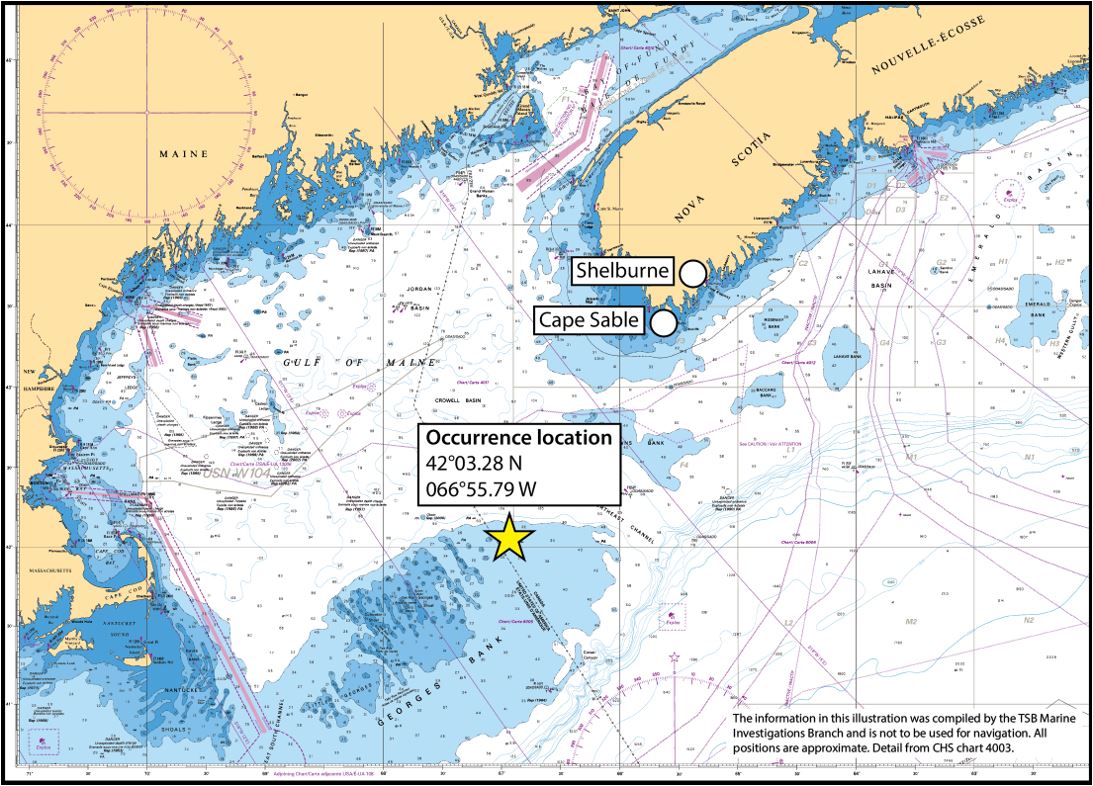

On 04 December 2024, the Fundy Leader, with the master and 12 crew members on board, departed Shelburne, Nova Scotia, to fish scallops. On 06 December, the vessel was about 100 nautical miles southwest of Cape Sable, Nova Scotia (Figure 3).

At approximately 2115,All times are Atlantic Standard Time (Coordinated Universal Time minus 4 hours). the master was in the wheelhouse operating the controls to haul the fishing gear when he noticed smoke near the electrical panel vents. The master asked the engineer to investigate the source of the smoke. Initially, the smoke was thought to be from an electrical fire, and so the engineer proceeded to the engine room to shut off the power to the wheelhouse and accommodations. The engineer passed by the exhaust pipes while entering the engine room but saw no signs of smoke or fire. Once in the engine room, the engineer turned off the power to the wheelhouse and accommodations. The very high frequency (VHF) radios remained powered using the emergency battery supply.

Meanwhile, the mate, who had been resting in the cabin just forward of the exhaust trunking, got up because he smelled smoke. He checked the galley, which was adjacent to the cabin, for the source of the smoke but did not find anything. He then returned to the cabin to see smoke coming from a seam in the cabin’s wall panelling. The mate informed the engineer, who was by then in the hallway. The engineer grabbed a nearby fire axe and made a hole in the cabin’s wall panelling to try to determine if the smoke was coming from the space behind the panelling attached to the bulkhead that separated the exhaust trunking from the accommodations. Although the handle on the fire axe broke while he was using it, the engineer was able to make a hole and determine that there were flames in the space between the panelling and the bulkhead. By this time, the master had activated the fire alarm and the crew members were mustering.

The 2 crew members assigned to form the fire team donned the firefighting suits and breathing apparatuses. They had also readied the fire pump and hoses and portable fire extinguishers. At approximately 2130, the fire team entered the cabin and enlarged the hole in the wall panelling with another fire axe. The handle on this fire axe also broke.The fire axes on the vessel had wooden handles. During firefighting efforts, the crew members used 3 fire axes; each time, the wooden handle broke. It is not known when the 3rd one broke. Smoke and flames were visible behind the wall panelling. The fire team began using portable fire extinguishers and water from the fire hoses to fight the fire in the bulkhead.

At 2140, the master used a VHF radio to call 2 other company fishing vessels that were in the area, the Atlantic Preserver and the Atlantic Protector, to notify them of the fire on board and request that they stand by. At approximately 2152, a crew member on the Atlantic Preserver used a satellite phone to notify the company’s operations manager of the fire. By approximately 2300, the fire team had the fire under control.

At 2304, a crew member on the Atlantic Preserver reported the incident to the Joint Rescue Coordination Centre (JRCC) Halifax via satellite phone. JRCC tasked the Canadian Coast Guard ship Sir William Alexander to respond. JRCC did not broadcast a Mayday since the fire was reported to be under control.

At 2310, the fire flared up again. The fire team resumed firefighting and, at approximately 2345, the fire was extinguished. Damage from the fire was localized to the bulkhead separating the exhaust trunking from the accommodations. On 07 December, at approximately 0046, the Fundy Leader departed for Shelburne under its own power, escorted by the Atlantic Preserver. At approximately 0640, the Canadian Coast Guard ship Sir William Alexander took over the escort from the Atlantic Preserver. At approximately 2000, the Fundy Leader arrived in Shelburne.

Origin of the fire

Data collected post-occurrence indicated that the source of ignition originated from a crack in the main engine exhaust silencer. The crack was approximately 30 cm in length and near the top of the silencer, on the side that faced the bulkhead separating the exhaust trunking from the cabin. Low‑flame‑spreadLow‑flame‑spread means that the surface will restrict the spread of flames in accordance with Transport Canada requirements. For more details, see Transport Canada, C.R.C., c. 1435, Large Fishing Vessel Inspection Regulations (as amended 21 February 2023), section 25(19). wall panelling was attached to the wood framing on the side of the bulkhead facing the cabin.

In this occurrence, hot exhaust gases were escaping from the cracked silencer and heating up the steel on the bulkhead, which was less than 10 cm away. By conduction, the heated steel ignited the wood framing and caused the fire (Figure 4).

Structural fire protection

Incorporating structural fire protection on a vessel is a way to reduce the likelihood of a fire. It involves designing the structure of the vessel to contain any outbreaks of fire to as small an area as possible. Structural fire protection may involve such things as restricting the use of combustible materials in the construction of the vessel, and separating accommodation spaces from the rest of the vessel by constructing thermal and structural boundaries.

The Large Fishing Vessel Inspection Regulations require certain areas of large fishing vessels to have low‑flame‑spread characteristics.These characteristics consist of exposed surfaces in corridors, stairway enclosures, and control stations; deck surfaces within accommodation spaces, control stations, corridors, and service spaces; and surfaces in concealed or inaccessible spaces in accommodation and service spaces. [Source: Transport Canada, C.R.C., c. 1435, Large Fishing Vessel Inspection Regulations (as amended 21 February 2023), sections 25(16) and 25(18)]. The regulations do not have requirements regarding structural materials used for hulls, decks, and bulkheads. Wood construction is permitted for all parts of a large fishing vessel’s structure provided that the exposed surfaces meet Transport Canada’s requirements for low‑flame‑spread characteristics. There are no structural fire protection requirements for small fishing vessels, that is, fishing vessels with a gross tonnage of not more than 150 and a length of not more than 24.4 m.

The Fundy Leader met the requirements of the Large Fishing Vessel Inspection Regulations for low‑flame‑spread characteristics.

Inspecting exhaust pipes

The main engine exhaust pipe (including the silencer) was covered with a type of lagging that could not be removed without damaging the lagging. The pipe was located next to a generator exhaust pipe. Both pipes were in a small area adjacent to the bulkhead, which meant that it was difficult to visually inspect the entire circumference of either. Exhaust trunking on fishing vessels typically provides limited access to exhaust pipes.

Large fishing vessels like the Fundy Leader fall under Transport Canada’s Delegated Statutory Inspection Program and are subject to periodic inspections by recognized organizations.Recognized organizations are classification societies that have been delegated authority by Transport Canada to perform inspections and issue certificates on behalf of Transport Canada. At the time of the occurrence, the Fundy Leader was certified by the recognized organization Lloyd’s Register, on behalf of Transport Canada. Exhaust pipes and silencers may be inspected by recognized organizations for signs of damage, leaks, and degradation, but this is typically limited to a visual inspection without removing the lagging. The last inspection conducted by the recognized organization was on 15 October 2024. During this inspection, the exhaust pipes and silencers were observed to have intact lagging.

It was not possible to determine how long the crack in the silencer had been present on the Fundy Leader prior to the occurrence. Some signs of a crack in a silencer may include visible discolouration of lagging or increases in noise, exhaust odours, or heat. The master and the crew members on the Fundy Leader were unaware of the crack in the silencer before the occurrence. The silencer was original to the construction of the vessel.

Safety action taken

Following the occurrence, Clearwater Seafoods instructed the master of the Fundy Leader to check the temperature of the exhaust pipes and trunking with an infrared thermometer during each voyage.

The sections of exhaust lagging damaged in the fire were replaced with a type of lagging that can be removed for inspections by vessel crew and regulators.

During vessel repairs post-occurrence, the company that owns and operates the Fundy Leader removed the remaining wood framing in the bulkheads separating the cabin and galley from the exhaust trunking. Metal framing was installed in its place. The wooden fire axe handles were replaced with fibreglass handles.

Safety messages

The TSB routinely communicates that meeting regulatory requirements ensures only a minimum level of safety. Even though regulations permit structures around exhaust trunking on fishing vessels to be constructed of combustible materials, vessel builders and owners must consider whether this is safe for their vessel. Where possible, combustible materials should be eliminated and, if they cannot be eliminated, must be protected from potential fire hazards.

Vessel exhaust pipes and silencers may pose a fire hazard in the event they sustain cracks or other failures. It is important that vessel owners and masters ensure these pipes and silencers are inspected and maintained regularly and that vessel builders design exhaust trunking and lagging to facilitate access to pipes and silencers for inspection and maintenance.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 27 August 2025. It was officially released on 11 September 2025.