Employee injury

Essex Terminal Railway Company

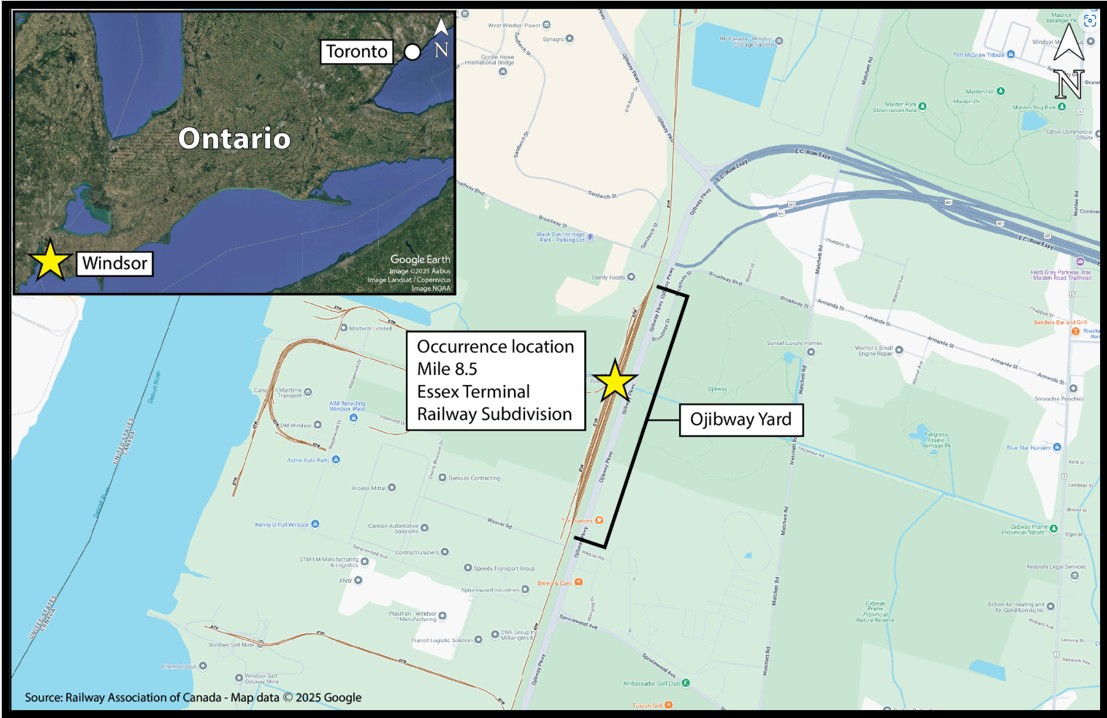

Mile 8.5, Essex Terminal Railway Subdivision

Windsor, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

The occurrence

On 16 February 2025 at approximately 1000,All times are Eastern Standard Time. the crew of Essex Terminal Railway Company (ETR)Essex Terminal Railway Company is a federally regulated short line railway that operates about 54 km of track in Ontario, starting from the east side of Windsor and ending in Amherstburg. yard assignment 0700 was conducting switching operations at the Ojibway Yard (Mile 8.5 of the Essex Terminal Railway Subdivision) in Windsor, Ontario (Figure 1), when 2 kicked rail carsKicking is a switching operation that consists of uncoupling one or more cars in motion and allowing them to roll under their own momentum to a specifically designated track. travelling at about 5 mph struck a maintenance-of-way (MOW) employee standing between the rails of the lead track. At the time of the occurrence, the MOW employee was clearing snow from switch points, using a gas-powered leaf blower strapped to his back. The MOW employee sustained serious injuries.

At the time of the occurrence, it was –2 °C and cloudy, with a northwest wind ranging from 40 to 60 km/h. About 5 cm of snow covered the ground and the rails were partially clear.

Events leading to the occurrence

The crew of yard assignment 0700, a locomotive engineer, a conductor, and a brakeman,The brakeman was also a qualified conductor. began their shift at 0700. The MOW employee, who was the only track maintenance employee working at the yard that morning, was already on duty, clearing snow from switches. All employees were qualified by ETR for their respective positions and familiar with the territory. The MOW employee had 13 months of experience, the conductor and the brakeman had about 14 months, and the locomotive engineer had over 16 years.

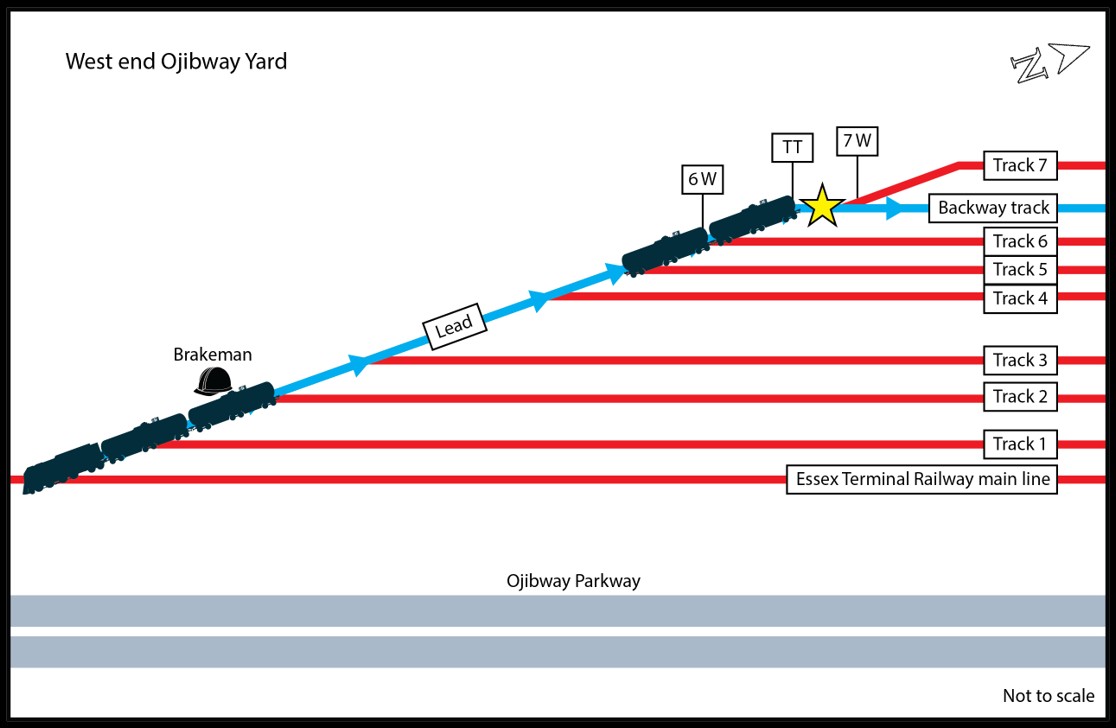

At approximately 0940, the crew were at the west end of the yard, preparing for their next switching move, which would involve kicking 2 coupled tank cars eastward on the lead track toward the Backway track, located between tracks 6 and 7 (Figure 2).

Meanwhile, the MOW employee arrived at the west end of the yard. He conducted a job briefing with the brakeman and then a separate job briefing with the conductor. He used the job briefings mainly to make his presence known to the crew. After the job briefings, the MOW employee resumed clearing snow from the switches.

At about 1000, the conductor, located near the 6W switch, looked eastward to ensure that the MOW employee was not in the intended path of the cars; he saw the MOW employee about 20 feet clear of the lead track. The conductor then communicated with the brakeman to kick the 2 tank cars. The brakeman, located near the main line switch, kicked the 2 cars eastward. After the cars were released, the conductor lost sight of the MOW employee and entrained the leading car to regain sight of him.

Unaware of the cars rolling eastward, the MOW employee changed location and placed himself between the rails of the lead track, between switches TT and 7W; at this location, he was directly in the path of the cars, which were travelling at about 5 mph. The MOW employee was facing in the direction of the approaching cars but was looking down. The conductor shouted to warn him, but the MOW employee did not hear him due to the noise of the leaf blower.

The MOW employee was struck by the leading car, causing him to spin and fall face down between the rails. The leaf blower caught on the underside of the leading car, pulling the MOW employee’s arms and coat over his head as the cars passed over him. The rail cars continued to travel toward the Backway track. The MOW employee sustained serious injuries and was transported to hospital.

Protection of track work on non-main track

MOW employees at ETR are required to ensure that proper track protection is in place before working on a track.Essex Terminal Railway Company, Engineering Safety Rule Book for Maintenance of Way Employees, section E-7: On or About Tracks, p. 10 [the document is not dated].

As a form of track protection when clearing snow from switches at Ojibway Yard, the practice was for MOW employees to rely on an awareness of their surroundings and communication with switching and other employees. Operating crews and MOW employees did not usually work simultaneously in the yard.

The Canadian Rail Operating Rules (CROR) state required forms of protection when performing track work (the definition of track work in the CROR does not include snow clearing from switches). For work on non-main track where the kicking of equipment is permitted,ETR special instructions permit kicking within Ojibway Yard, in accordance with Rule 113.5 of the Canadian Rail Operating Rules. (Source: Essex Terminal Railway Company, Rule Book for Train & Engine Employees, section 1.7: Kicking Equipment, May 2024). the acceptable forms of protection are indicated in Rule 841.

Rule 841 states, in part:

PROTECTION OF TRACK WORK ON NON-MAIN TRACK AND IN CAUTIONARY LIMITS

[…]

(b) When working limits are on a track where the kicking of equipment is permitted per Rule 113.5(a), protection must be provided by (c)(i) or (iii).

(c) The foreman must provide protection to prevent access to the working limits using one or more of the following methods:

(i) lock switch(es) with a special lock, in a position to prevent a movement from entering the working limits;

(ii) place a red flag by day, and in addition, a red light by night, or when day signals cannot be plainly seen, between the rails to prevent a movement from entering the working limits. Such signal(s) must be placed at least 100 yards from the working point where practicable, where there will be a clear view of the signal(s) from an approaching movement of at least 300 yards. If there is equipment on the track which will prevent a clear view of 300 yards, the red signals must be placed to include such equipment; or

(iii) a red signal displayed per (ii) and a derail locked in the derailing position with a special lock.Canadian Rail Operating Rules (28 January 2025, approved by Transport Canada 24 January 2025), Rule 841: Protection of Track Work on Non-Main Track and in Cautionary Limits, p. 100.

Although ETR’s Engineering Safety Rule Book for Maintenance of Way Employees requires that proper track protection be in place before working on a track, CROR Rule 841 is not referenced in this rule book. However, Rule 841 is included in ETR’s Essex Terminal Railway Employee HandbookThe Essex Terminal Railway Employee Handbook is a binder collating several printed documents that contain safe work policies and procedures applicable to all employees as well as role-specific safety information. and in rules training material. There were no specific instructions or procedures at Ojibway Yard to lock out and flag tracks for protection when clearing snow from switches. In this occurrence, the MOW employee did not place red flags between the rails or lock out the switches.

Operating practices related to communications

Clear, well understood communication is critical to safe railway operations. ETR states its communication expectations in its Rule Book for Train & Engine EmployeesEssex Terminal Railway Company, Rule Book for Train & Engine Employees, May 2024. and Engineering Safety Rule Book for Maintenance of Way Employees.Essex Terminal Railway Company, Engineering Safety Rule Book for Maintenance of Way Employees [the document is not dated].

In this occurrence, upon arriving at the west end of the yard, the MOW employee held a job briefing with the brakeman and a separate one with the conductor. Job briefings are intended for employees to discuss the planned work, their responsibilities, the relevant hazards, ways to eliminate hazards or protect against them, and the type of protection provided to carry out the work. However, in this instance, the job briefings did not cover hazards or protection. More specifically, a detailed discussion about what switching moves the crew would carry out, the intended path of the cars, and the MOW employee’s planned location during these moves were not discussed. Also, the separate job briefings could have made it difficult for the crew and the MOW employee to establish shared situational awareness. In a kicking operation, the absence of a shared situational awareness can result in a misunderstanding of where each team member is located and what they are doing.

In addition, the MOW employee was not provided a radio, and therefore the crew could not communicate directly with him to confirm his location, and the MOW employee could not monitor communications between the crew members to keep informed of their activities.

When needing to communicate with his supervisor or yard coordinator, the MOW employee typically used his personal cell phone.

Rules compliance at Ojibway Yard

ETR regularly conducts oversight (proficiency tests) of its employees to evaluate the extent to which they comply with rules, regulations, standards, and procedures. In 2024, ETR conducted several proficiency tests, 6 of which were on the MOW employee and 15 on the operating crew. None of these tests covered MOW protection.

Safety action taken

After the occurrence, ETR revised the General Operating Instructions, the Essex Terminal Railway Time Table, and the Engineering Safety Rule Book for Maintenance of Way Employees. In particular, the company implemented a procedure for clearing snow from switches. This procedure now requires MOW employees to lock out and flag tracks before clearing snow. It also stipulates that all switching operations must be stopped until MOW employees have completed snow clearing or have cleared the tracks, and that operating crews may not get back onto the tracks until they have approval from the yard coordinator and from MOW personnel.

The railway established a policy that operating crews and MOW employees may not both operate in Ojibway Yard at the same time.

ETR has also equipped its MOW employees with radios.

Safety messages

It is important for employees working in yards to conduct comprehensive job briefings to establish a shared situational awareness of roles, work limits, protection measures, communication protocols, and emergency procedures.

Employees working in yards must have adequate equipment to maintain shared situational awareness and communicate their work and yard movements.

To prevent occurrences between switching movements and MOW employees, it is vital that railway companies provide clear instruction on the type of protection required during these operations.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 27 August 2025. It was officially released on 18 September 2025.