Movement exceeds limits of authority

VIA Rail Canada Inc.

Passenger train P06431-29

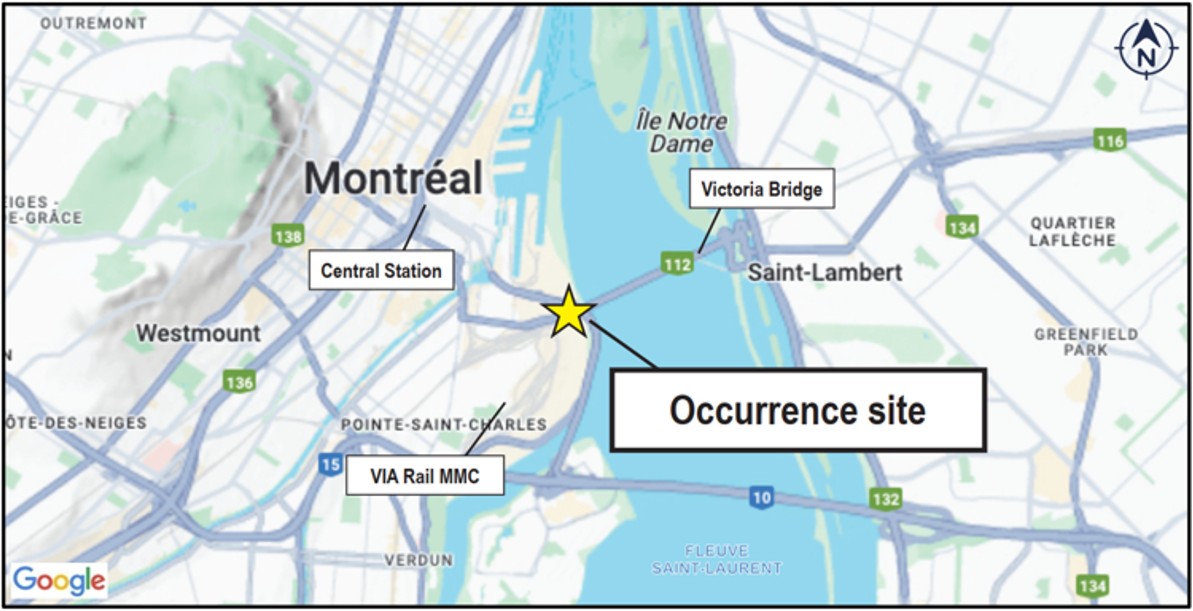

Mile 72.3, Canadian National Railway Company (CN) St-Hyacinthe Subdivision

Montréal, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

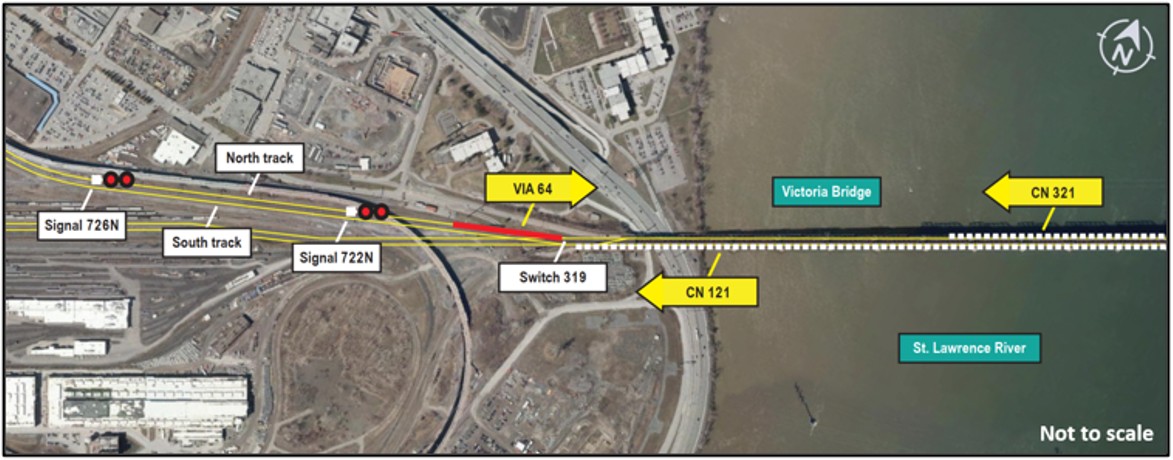

On 29 September 2024, at approximately 1733 Eastern Daylight Time, VIA Rail Canada Inc. passenger train P06431-29 (VIA 64) was shoving eastward at a speed of approximately 10 mph when it passed a signal displaying a Stop indication without authorization at Mile 72.3 of the Canadian National Railway Company (CN) St-Hyacinthe Subdivision. The train came to a stop approximately 1500 feet past the signal when it ran through a main-track switch at the entrance to Victoria Bridge in Montréal, Quebec. A CN freight train (CN 321) travelling westward on the same track came to a stop approximately 1700 feet behind the tail end of VIA 64. There was no collision or derailment, and there were no injuries.

1.0 Factual information

Under section 28 of the Canadian Transportation Accident Investigation and Safety Board Act, every on board recording is privileged. However, the TSB may make use of any on-board recording where it is necessary in the interests of transportation safety. For this reason, while the Board may refer to an on-board recording where required to support a finding and identify a substantive safety deficiency, other parties may not access or use privileged on-board recordings. The reason for protecting on-board recordings lies in the premise that the privilege of a recording respects the privacy of operating personnel whose words and actions are captured on the recording and will also help ensure that this essential material is available for the benefit of safety investigations. This report references content from a locomotive voice and video recorder (LVVR), which is a form of on-board recording in the rail transportation sector. For each of these references, the TSB is using the LVVR recording to substantiate some of its findings and to identify certain substantive safety deficiencies. In each case, the material has been carefully examined to ensure that the extracts used are necessary to identify causes or contributing factors of this occurrence or to identify safety deficiencies.

1.1 The occurrence

On 29 September 2024, at approximately 1130,All times are Eastern Daylight Time. VIA Rail Canada Inc. (VIA) passenger train P06431-29 (VIA 64) left Toronto, Ontario, and proceeded eastbound to Montréal, Quebec, on the Canadian National Railway Company (CN) Kingston Subdivision. Train VIA 64 consisted of 1 locomotive and 7 light, rapid, and comfortable (LRC) passenger cars. It weighed about 498 tons and was about 654 feet long.

The train operating crew consisted of 2 qualified locomotive engineers: an operating locomotive engineer (LE) and an in-charge locomotive engineer (ICLE).

The train completed its journey as scheduled and arrived at the station in Montréal at approximately 1700. After the passengers and on-board personnel had disembarked, the crew received permission to take the train to VIA’s Montréal Maintenance Centre (MMC) located near the tracks at Central Station. During this routine manoeuvre, the train must back up to Victoria Bridge and take the crossover leading to the MMC (Figure 1).

During the shoving movement, the ICLE was on board the tail-end car (VIA 3357, which was the leading endThe leading end of the train is determined by the 1st rolling stock in the direction of movement. of the train) to protect the movement in accordance with Canadian Rail Operating Rules (CROR) Rule 115.

As VIA 64 was backing up, the CN rail traffic controller (RTC) contacted the crew on the radio at approximately 1718 to inform them that other trains would be passing on Victoria Bridge tracks before they could complete their move to the MMC.

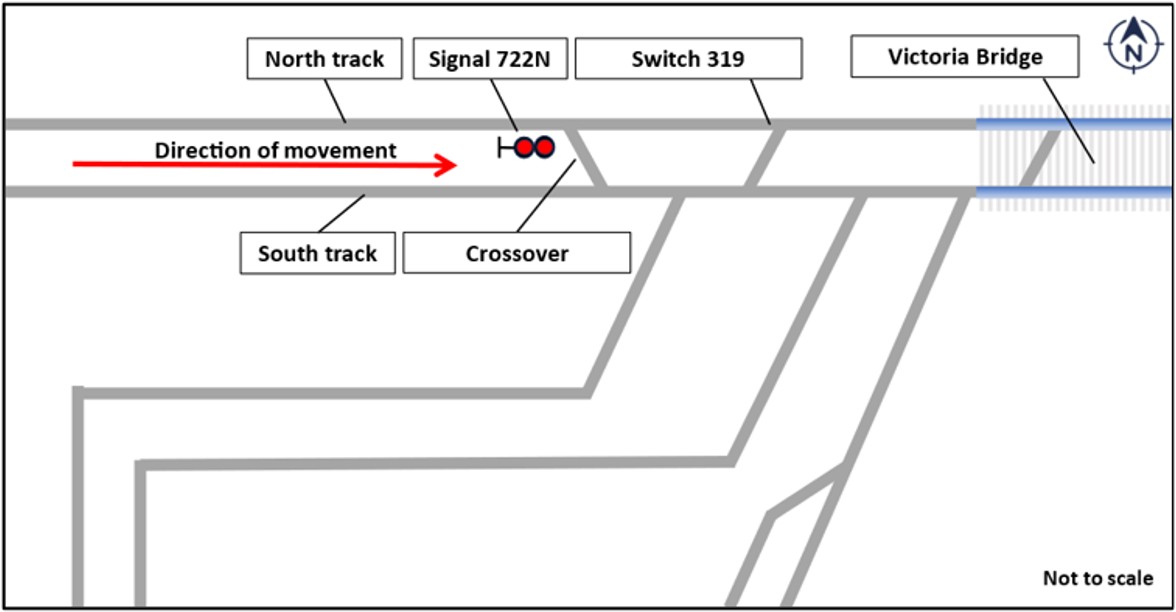

At approximately 1724, when the train arrived at Signal 726N,This signal is the advance signal for Signal 722N on the north track (see Figure 2). the signal was displaying a Medium to Stop indication (yellow on red aspect),Canadian Rail Operating Rules (CROR) (effective 01 October 2022), Rule 427, p. 75 (Transport Canada, approved 09 May 2022). instructing the train to prepare to stop at the next signal (Signal 722N). When Signal 722N became visible, the ICLE observed that it was displaying a Stop indication (red on red) and notified the LE over the radio. The LE applied the brakes, and the tail end of the train came to a stop just over 300 feet from Signal 722N.

At approximately 1732, 8 minutes after the train came to a stop,While VIA 64 was stopped and waiting for a permissive indication from Signal 722N, another train (VIA 14) passed by while backing up on the adjacent track (south track) toward Central Station. Furthermore, 2 freight trains were approaching westbound on the north and south tracks of Victoria Bridge (CN 321 and CN 121). the ICLE told the LE that he was having difficulty confirming the colour of the top light on Signal 722N. The ICLE asked the LE to back up 2 car lengthsA car length is about 85 feet. so that the tail end of the train would be closer to the signal and he could confirm its indication. As the tail end of the train approached Signal 722N, the ICLE perceived a change in the colour of the signal’s top light and determined that the light was yellow. He then interpreted the signal as displaying a permissive Medium to Stop indication (yellow on red aspect). He radioed the LE and asked him to continue shoving the train for 15 car lengths toward Victoria Bridge.

After travelling about 1500 feet past Signal 722N, the ICLE noticed that the north track switch, a dual control switchA switch equipped for both powered and hand operation. (switch 319) at the west end of Victoria Bridge, was not set for his train and immediately instructed the LE to stop the train.

The LE made a full service air brake application. When the train came to a stop, the truck at the end of the last car ran through the dual control switch. Upon noticing the situation, the crew immediately made an emergency call on the subdivision standby radio channel. This call coincided with the broadcast of an automated audio message from a nearby track detector, at the same time and on the same channel. These 2 simultaneous radio transmissions overlapped, rendering them unintelligible. The crew then placed an emergency call on the RTC channel.

At the same time, 2 freight trains were approaching the west end of Victoria Bridge. CN 121, which was on the south track, arrived alongside VIA 64 just as it was running through the switch. Seeing the situation, the CN 121 crew radioed the crew of the other freight train, CN 321, which was travelling westward on the same track as VIA 64, and asked them to stop their train immediately. The LE on CN 321, which was travelling at a speed of approximately 4 mph, immediately made a full service brake application. CN 321 stopped approximately 1700 feet from the tail end of VIA 64 (Figure 2).

At the time of the occurrence, the sky was clear, and the temperature was 18 °C.

1.2 Subdivision information

The St-Hyacinthe Subdivision belongs to CN and is part of the Québec–Windsor rail corridor. The subdivision comprises Class 5 double tracks, which handle approximately 14 exo commuter trains, 12 VIA passenger trains, and 12 freight trains per day, on either of the 2 main tracks and in both directions. At the western end of Victoria Bridge, the 2 main tracks split to allow trains to travel toward the Montréal Subdivision or Central Station. From Mile 72.96, the tracks are owned by Immeuble VDS, which takes care of their maintenance up to Central Station. Between 75 and 80 passenger trains travel each day on the tracks leading to Central Station. Train movements on the St-Hyacinthe Subdivision are governed by the Centralized Traffic Control system (CTC), as authorized by the CROR, and supervised by a CN RTC located in Edmonton, Alberta. In the area of the occurrence, the track is tangent and there are no gradients.

1.2.1 Wellington Territory

Between Saint-Lambert, Quebec, Mile 71.2, and Central Station, Mile 74, the 2 main tracks of the St-Hyacinthe Subdivision are part of interlocking limitsCanadian Rail Operating Rules (CROR) (effective 01 October 2022), Definitions, p. 10 (Transport Canada, approved 09 May 2022) defines interlocking limits as “[t]he tracks between the extreme or outer opposing interlocking signals of an interlocking.” known as the Wellington Territory. The CROR defines interlocking as “[a]n arrangement of interconnected signals and signal appliances for which interlocking rules and special instructions are in effect.”Canadian Rail Operating Rules (CROR) (effective 01 October 2022), Definitions, p. 10 (Transport Canada, approved 09 May 2022). Interlocking systems are designed so that a movement cannot obtain a permissive signal unless all safety conditions necessary for that movement are confirmed by the system. Interlockings can be manually operated, remotely controlled, automatic, or locally controlled. In the Wellington Territory, the interlocking limits are remotely controlled by the CN RTC in Edmonton.

1.3 Recorded information

The TSB obtained the downloaded data from the event recorder of the locomotive of VIA 64, the recordings from its forward-facing camera, the data from its LVVR, the recordings from the forward-facing cameras of freight trains CN 121 and CN 321, the railway signalling system records, the audio recordings of the subdivision radio standby channel and the RTC radio channel, and the video recordings from the Ministère des Transports et de la Mobilité durable du Québec cameras and the Réseau express métropolitain (REM) cameras located in the occurrence area. These data helped to establish the sequence of events.

Finding: Other

The presence of numerous surveillance cameras in the occurrence area enabled the TSB to gather information relevant to the investigation.

1.4 Crew information

The VIA 64 crew members were qualified for their respective positions, were familiar with the territory, and met established rest and fitness requirements. The LE had about 14 years of experience in train operations, and started working as an LE for VIA in May 2016. The ICLE had about 10 years of experience in train operations, and started working as an LE for VIA in April 2017.

1.5 Signal information

1.5.1 Signal 722N

Signal 722N controls the route of trains to Victoria Bridge or between the north and south tracks via a crossoverCanadian Rail Operating Rules (CROR) (effective 01 October 2022), Definitions, p. 8 (Transport Canada, approved 09 May 2022) defines crossover as “[a] track joining adjacent main tracks, or a main track and another track.” (Figure 3).

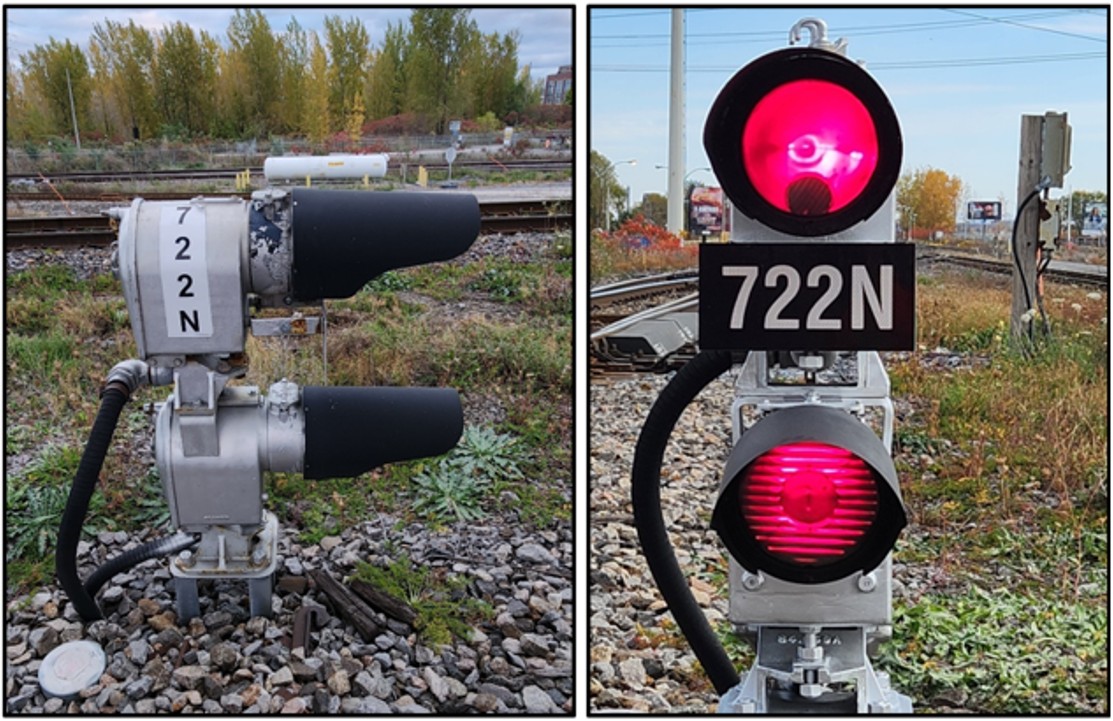

Signal 722N is a 4-foot-high low-mast style H-2 searchlight signal manufactured by Union Switch and Signal. It is located between the north and south tracks and, according to CN, is aligned for optimal visibility from a distance of 100 feet and 588 feet. This type of signal began production in the 1920s and consists of 2 superimposed lights equipped with mobile lens mechanisms. Each light has an extended hoodFollowing an incident in 2006 where it was determined that sunlight may have caused the top light to appear yellowish, the signal lights were fitted with extended hoods to reduce the risk of interference (TSB Rail Transportation Occurrence R06Q0090). that improves the visibility of the light beam from a distance (Figure 4).

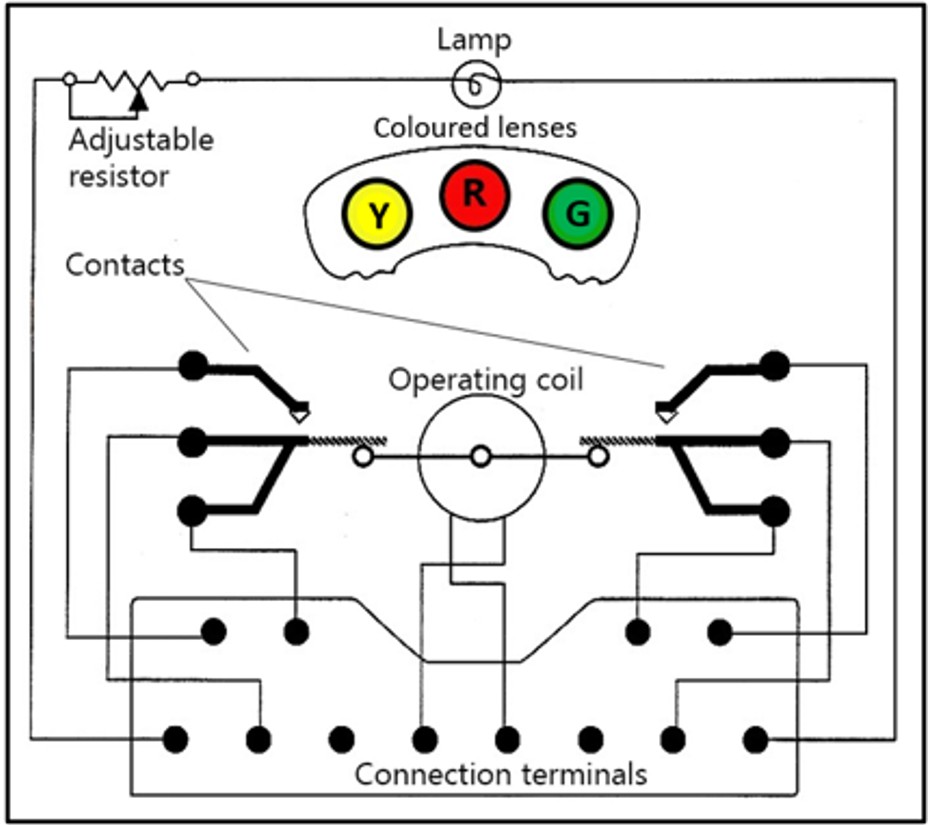

Each light is equipped with 3 coloured lenses (one yellow, one red, and one green) that can be moved in front of the lamp’s light beam with an electrically controlled 3-position mechanism. Electrical connections enable the system to confirm the position of the colour lenses (Figure 5).

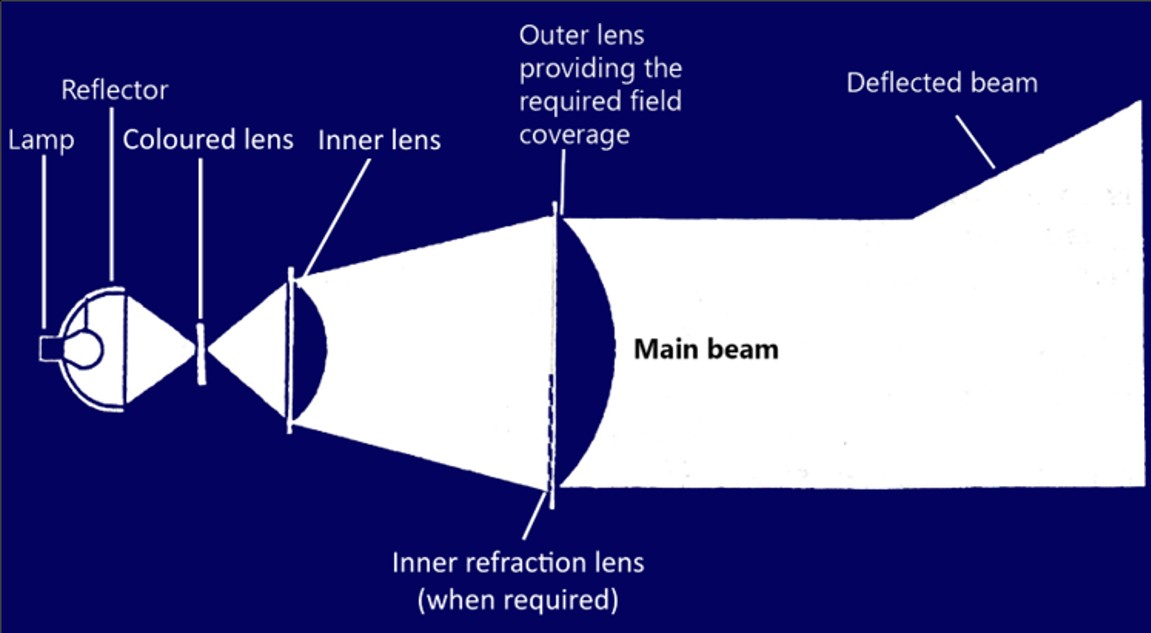

The light beam emitted by the incandescent lamp is reflected by a reflector and passes through the coloured lens, an inner lens, a refraction lens,When necessary. and an outer lens.Standard lens, refractive lens, or spread lens. These components are selected and arranged to direct the light beam according to the profile of the track and the topography of the terrain, taking into account the location of the signal (Figure 6).

1.6 Signal system in the Wellington Territory

The system that controls the interlocking signals in the Wellington Territory is installed in a bungalow near the track, not far from Signal 722N. The vital processor interlocking (VPI) receives commands from the Edmonton Control Centre and the occupancy status of the blocks in the interlocking, and controls the signal indications based on route requests made by the RTC. The VPI also receives all signal indications in real time. All of these data are compiled in electronic records in the form of codes.

The TSB collected and verified these records. These indicated that Signal 722N was displaying a Stop indication when VIA 64 passed it.

The TSB also examined the components of the signalling system and Signal 722N. The examination revealed that the signalling system was operating as designed and that the optical, electrical, and mechanical components of Signal 722N were in good condition.

1.6.1 Outer lenses of Signal 722N

Signal 722N has 2 different types of outer lenses.

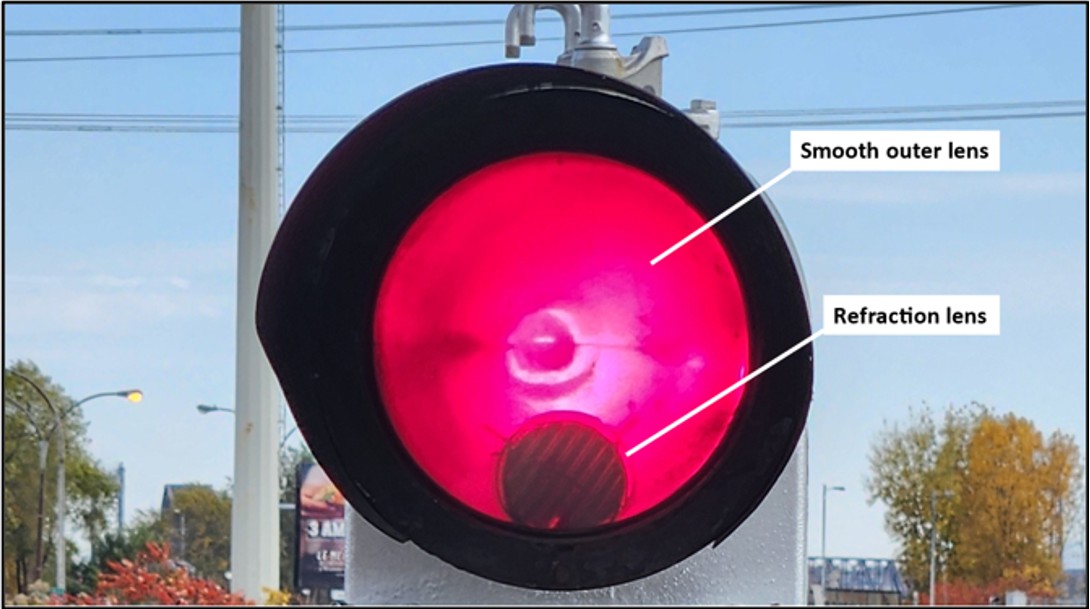

The top light is equipped with a smooth outer lensThis type of lens is generally used where the signal approach path is tangent for a distance of 1000 feet or more. combined with a refraction lens placed behind the lens (Figure 7). A smooth lens produces a specular reflection, which acts like a mirror by directionally reflecting incident sunlight.

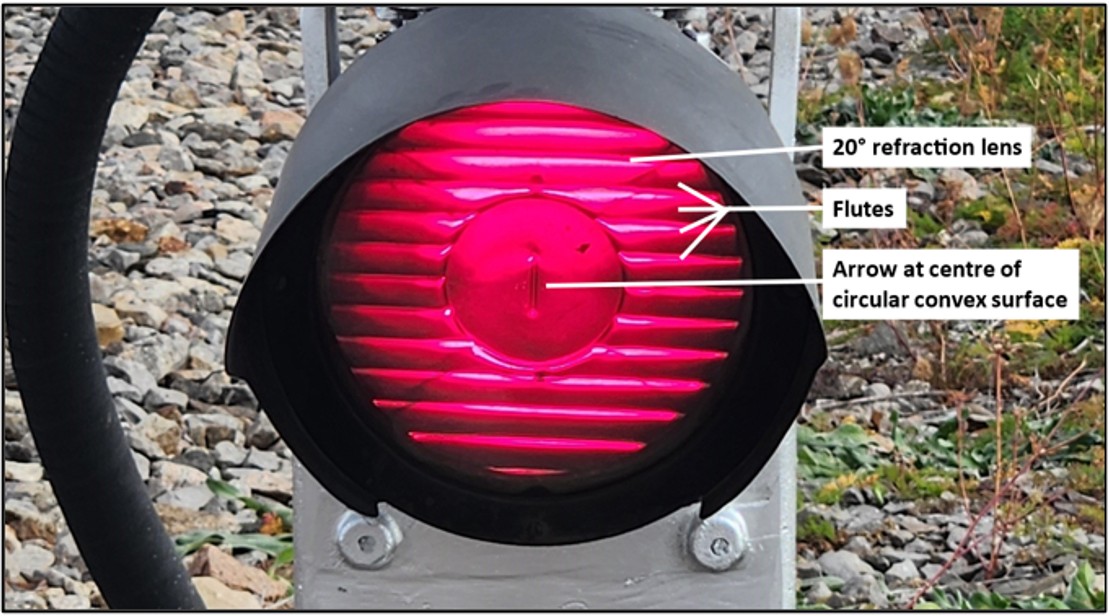

The bottom light has a 20° external refraction lens, which is installed in a way that concentrates the light beam emitted by the light at an angle of 20° upwards. This type of lens has flutes and a smooth convex surface in the centre. An arrow in the centre of the smooth surface makes it possible to adjust the orientation of the lens and the light beam to suit the topographical conditions on the ground (Figure 8).

A fluted lens produces a diffuse reflection, where the flutes disperse the incident sunlight in several directions.

Signal 722N is the only signal in the interlocking limits that features 2 different types of lenses. Signal 722S, which is located at the same height on the south track, has 2 standard smooth lenses. The investigation was unable to determine why Signal 722N was equipped with different lenses.

1.6.2 Impact of defocusing on the perception of red lights

Defocusing of light occurs when incident light reflected from a surface is scattered, resulting in a loss of sharpness in the observed reflection. The degree of scattering depends on the type of surface on which the light is reflected. The smoother or more regular the surface (such as the smooth lens of the top light of Signal 722N), the more specular the reflection, resulting in low defocusing. On the other hand, the rougher or more irregular the surface (such as the fluted lens of the bottom light of Signal 722N), the more diffuse the reflection and the greater the defocusing.

According to a study,J. M. Wood, D .A. Atchison, and A. Chaparro, “When Red Lights Look Yellow,” Investigative Ophthalmology & Visual Science Vol. 46, Issue 11 (2005), pp. 4348–4352. in certain conditions, a red light may appear yellowish to an observer when the incident light, reflected by the surface of the outer lens of the light, causes slight defocusing.

A “phantom” aspect is the perception of a colour that is not produced by the signal light itself but is caused by sunlight or reflections on the lenses. Signal lights that are likely to exhibit such issues are generally ones that are directly facing sunlight, for example, early in the morning or late in the afternoon.

Such signals may be equipped with extended hoods, where appropriate,Metrolinx, GO Transit Signals & Communications Standards – Signal Sighting Distance Design Standard, Standard RC-0506-03SIG-04, revision 1 (February 2021), section 3.2: Signal Sighting Hazards, paragraph 3.2.9: Phantom Aspects, p. 4. to counteract this phenomenon. In this occurrence, the lights of Signal 722N were equipped with extended hoods.

1.7 Signal configuration and operating speed in the Wellington Territory interlocking limits

The signalling system within the Wellington Territory interlocking limits was installed before the implementation of CROR signal indications. As a result, low-mast signals in this area do not display route or speed information.With the exception of the Restricting signal indication. These signals only display authority to occupy the track up to the next signal. The maximum allowable speedsMovements in this area take place at low speeds, i.e., 20 mph or less. are specified in the summary bulletin or division timetable.At the time of the occurrence, these instructions were in the summary bulletin, where it was specified that they should be added to section 4.3 of the Champlain Division, St-Hyacinthe Subdivision timetable. This set of instructions has since been incorporated into the timetable. (Canadian National Railway Company, Eastern Region: Champlain Division Time Table 87, Operating Practices [effective 0001, 01 November 2024], section 4: Interlockings, p. 172.)

This situation was assessed by Transport Canada (TC) during inspections conducted between December 2022 and April 2023.These inspections were carried out following a complaint received. TC determined that the signal sequences did not comply with the CROR and that the situation could cause confusion and increase the risk of accidents. CN and Immeuble VDS acknowledged this situation and indicated that they planned to gradually modernize the system at this location. In the meantime, the maximum speed was reduced to 15 mph in certain areas. At the time of publication of this report, the signals had not been updated.

During this occurrence, VIA 64 was operating within the applicable speed limits.

1.8 Rules of the Canadian Rail Operating Rules

CROR Rule 123.2, Switching by Radio, states (in part):

(iv) the indication of block and interlocking signals affecting their movement, must be communicated between crew members while switching; […]Canadian Rail Operating Rules (CROR) (effective 01 October 2022), Rule 123.2 (iv), p. 67 (Transport Canada, approved 09 May 2022).

CROR Rule 34, Fixed Signal Recognition and Compliance, states (in part):

[…]

(b) Crew members within physical hearing range must communicate to each other, in a clear and audible manner, the indication by name, of each fixed signal they are required to identify. Each signal affecting their movement must be called out as soon as it is positively identified, but crew members must watch for and promptly communicate and act on any change of indication which may occur. [emphasis added]Ibid., Rule 34, p. 27.

[…]

In this occurrence, while the leading end of the train was approaching Signal 722N, the ICLE perceived a change in the colour of the signal’s top light and informed the LE over the radio that the signal was displaying a Medium to Stop indication. The LE, who could not see the signal from the locomotive cab, acknowledged this permissive indication and the train continued. As the train was backing up, the ICLE maintained visual contact with the signal. He did not notice any further changes in the signal indication’s aspect while the signal remained in his field of vision.

1.9 Other similar occurrences

The TSB’s Railway Occurrence Database System (RODS) has recorded at least 4 other occurrencesTSB rail transportation occurrences R25W0036, R23S0018, R06Q0090, and R00C0121. that happened in Canada from January 2000 to August 2025 involving misperception of signal indications. In all 4 cases, the data showed that the crew saw yellow lights instead of red lights because sunlight reflected off the outer lens of the signal lights.

Furthermore, for that same period, the TSB has recorded 21 occurrencesTSB rail transportation occurrences R22D0031, R22D0002, R21D0078, R20D0040, R19D0086, R19D0045, R19D0019, R17D0087, R15D0027, R13D0075, R12D0105, R10D0084, R08D0044, R06Q0090, R05D0048, R03D0125, R02D0106, R01D0110, R01D0081, R00D0137, and R00D0119. in which trains passed Stop signal indications in the Wellington Territory interlocking limits. EightTSB rail transportation occurrences R17D0087, R15D0027, R13D0075, R12D0105, R10D0084, R06Q0090, R05D0048, and R01D0110. of these occurrences took place during shoving movements.

In particular, on 17 August 2006, at approximately 1806,At that time, the sun was at an altitude of 18.55° above the horizon and at an azimuth of 270.24°. VIA 39 was performing a shoving movement from Montréal Central Station toward Victoria Bridge when it passed Signal 324R,The signal is the same one involved in this occurrence and has since been renumbered 722N. which was displaying a Stop indication, without authorization.TSB Rail Transportation Occurrence R06Q0090. The ICLE, who was stationed in the vestibule of the last car to protect the movement, then informed the LE of a Medium to Stop indication on that signal.

VIA’s internal investigation determined that, at the time of the occurrence, the sun was reflecting off the signal. A CN signal maintainer dispatched immediately to the scene confirmed that the top light of the signal had a yellowish tint despite the fact that the signal was displaying a Stop indication (red on red aspect). A VIA investigator determined that the sun’s reflection on the outer lens may have caused the upper light to appear yellow. Following this incident, CN fitted the signal with extended hoods to reduce the risk of interference from sunlight reflecting off the signal lenses.Apart from this occurrence, there have been no occurrences reported to the TSB involving misperception of this signal indication.

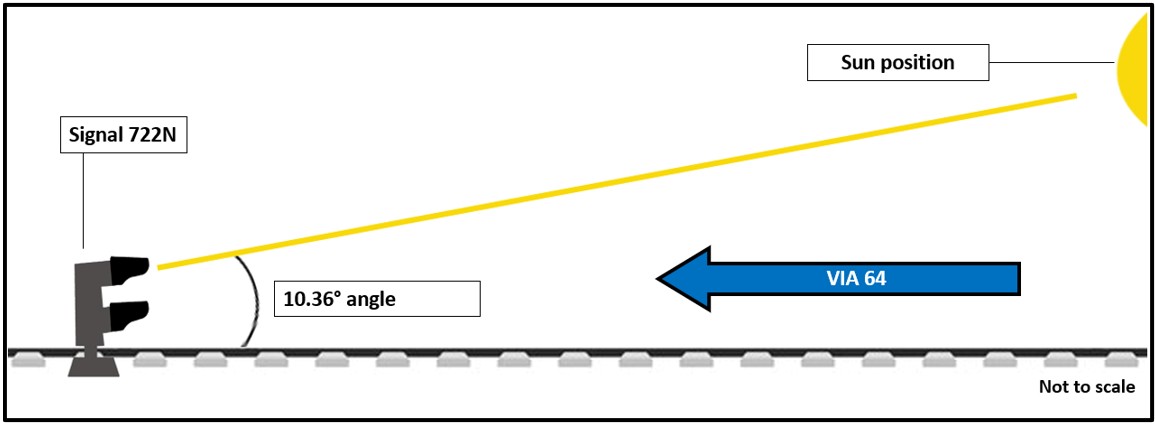

1.10 Position of the sun at the time of the occurrence

At the time of the occurrence, the sun was 10.36°At this low altitude, as sunset approaches, the light takes on orange and reddish hues due to atmospheric scattering, which can vary depending on humidity, temperature, pressure, and the presence of particles in the air. above the horizon and at a 255.11° azimuth at Signal 722N. According to data from the Ministère des Transports et de la Mobilité durable du Québec and REM surveillance cameras, as well as the forward-facing camera on the lead locomotive of VIA 64, the sky was clear and the sun was facing the signal and shining directly on its lenses (Figure 9).

1.11 Visual perception

Crew members’ accurate and timely visual perception of railway signals is essential for compliance. This visual perception is the 1st step in a sequential process that involves identifying signals and interpreting them correctly. The subsequent action taken by the crew includes the following steps: recognize and call, confirm the indication between crew members, and adjust the train handling and/or speed accordingly.

1.11.1 Railway Medical Rules for Positions Critical to Safe Railway Operations and colour perception

People in positions critical to rail safety must undergo the medical examinations specified in the Railway Medical Rules for Positions Critical to Safe Railway Operations.Transport Canada, Railway Medical Rules for Positions Critical to Safe Railway Operations (effective 22 December 2006). Tests include assessment of close and distant vision, field of vision, colour vision, and eye muscle balance, which are carried out every 5 years until the age of 40 and every 3 years thereafter as part of the periodic medical examination.

The ICLE in this occurrence had undergone a comprehensive eye examination, including a colour vision assessment,According to VIA requirements, locomotive engineers must undergo a medical examination every 3 years. at the VIA Chief Medical Officer’s office in 2022.The Ishihara colour vision test is designed to produce accurate results for determining colour blindness and the degree of colour blindness. No medical conditions were noted.

1.12 Situational awareness and mental model

Situational awareness is the perception of the elements in the environment, the comprehension of their meaning and the projection of their status in the future.M. R. Endsley, “Situation Awareness”, in G. Salvendy and W. Karwowski (eds.), Handbook of Human Factors and Ergonomics, 5th edition (John Wiley & Sons Inc., 2021), pp. 434–435. In a dynamic environment, situational awareness requires continuous extraction of information from the environment, integrating this information with relevant internal knowledge to create a coherent mental model, and using this model to anticipate future events.

A mental model is an organized internal structure that enables people to describe, explain, and predict events in their environment, and to develop expectations of what will happen in the future.E. Salas, F. Jentsch, and D. Maurino, Human Factors in Aviation, 2nd Edition (Academic Press, 2010), p. 266. When a mental model is adopted, it is resistant to change. New, compelling, and convincing information must be perceived and assimilated in order to modify an existing mental model.

1.13 VIA 64 emergency call

Immediately after noticing that the train had run through switch 319, the LE of VIA 64 placed an emergency call on the subdivision standby radio channel in accordance with CROR Rule 102. At the same time, a wayside detector located close by was transmitting an automated audio message to another train on the same channel. These 2 simultaneous radio transmissions overlapped, rendering them unintelligible to other crews on trains travelling nearby.CROR Rule 125(c), Emergency Communication Procedures, stipulates that an emergency communication has absolute priority over other transmissions. CN’s rail communication system is not equipped with an override that prioritizes emergency calls on the subdivision standby radio channel.

The LE of CN 121, which was approaching VIA 64, observed the situation and contacted the crew of CN 321, which was approaching on the north track, to tell them to stop their train.

After VIA 64 ran through switch 319, the necessary measures were taken to notify the authorities and secure movements in this area, in accordance with CROR requirements.

1.14 Handling of Rule 439 alarms

In this occurrence, the RTC received the Rule 439 alarm as soon as VIA 64 passed Signal 722N. As he was verifying the alarm, the emergency call from VIA 64 came in. In accordance with CN’s Rail Traffic Controller Manual, the RTC immediately ensured that freight train CN 321 had come to a stop before issuing the required clearances.

1.15 System safety defences in signalled territory

1.15.1 Administrative defences

To mitigate operational hazards, the railway industry in Canada relies heavily on administrative defences such as rules, policies, and procedures.

In signalled territory, the primary administrative defence is compliance with the CROR, which govern all federally regulated railways in Canada. For these rules to be effective, initial and recurrent training, as well as monitoring of compliance, are essential.

The effectiveness of the rules governing signal indications depends on a crew’s ability to detect signal indications, interpret them correctly, and respond appropriately. To do this, a train crew relies on environmental cues, previous experience, and memory.

In the complex and dynamic environment of rail transportation, situational awareness requires the train crew to continuously extract information from the environment and integrate it with their knowledge to create a coherent mental model of the situation that helps prioritize information and anticipate future events. In familiar territory, attention and expectations are driven by the crew’s existing mental model. However, attention is a limited cognitive resource that can be diverted from a primary task by external stimuli or internal thoughts.U.S. Department of Transportation, Federal Railroad Administration, Why do Passenger Trains Pass Stop Signals? A Systems View, DOT/FRA/ORD-19/19, Final Report (June 2019), p. 47, at https://railroads.dot.gov/sites/fra.dot.gov/files/2019-12/Passenger%20trains%20pass%20stop%20signals2.pdf (last accessed on 08 January 2026). When attention is directed toward information that is not critical to the task, it becomes a distraction. Distractions can impair the crew’s ability to detect and recognize signal indications. Memory lapses can also affect accurate recall of signal indications, particularly when attention is divided across multiple tasks.Ibid., p. 50. As attentional demands increase for other tasks, the retrieval of previously acquired information—such as the aspect of a recently observed signal—may be compromised.

These inherent limitations in human cognition are involuntary and cannot be entirely mitigated through training or procedural reinforcement. As a result, under certain conditions, signal indications may be missed, misinterpreted, or incorrectly called. When this occurs, the primary administrative defence fails.

To provide additional layers of defence, some railways have implemented company-specific procedures to supplement the CROR rules governing signal compliance.

For instance, to reduce or eliminate distractions, VIA has introduced the cab red zone—special procedures that require crew members to cease non-essential communication and tasks during safety-critical operations. CN has introduced similar procedures known as the critical focus zone. Although both these procedures are designed to reinforce crew focus, they remain subject to the same limitations as other administrative defences: if crew members do not recognize the conditions that place them in such zones, the defence is compromised.

Administrative defences, even when layered, still rely on strict crew adherence to rules and procedures and remain vulnerable to the inherent limitations of human cognition. These limitations underscore the need for additional layers of defence that do not rely solely on crew compliance to ensure the safe operation of trains.

1.15.2 Physical defences

To supplement administrative defences in signalled territory, railway operations in many countries have implemented physical defences in the form of automated train control systems. These automated systems are designed to intervene when crews take inappropriate actions in response to signal indications. The term “automated train control system” does not refer to a single technology or proprietary system, but rather to a group of certified implementations that function as safety overlays on top of existing train control systems. Examples include the European Train Control System (ETCS), the Automatic Train Stop – Pattern (ATS-P) system in Japan, the Advanced Train Management System (ATMS) in Australia, and the positive train control (PTC) system in the United States. Appendix A provides an overview of the PTC implementation in the United States.

Canada has not yet implemented an automated train control system. Canadian railways continue to rely on administrative defences. However, BNSF Railway has voluntarily implemented PTC on the New Westminster Subdivision in British Columbia.

The absence of mandatory physical, fail-safe defences capable of intervening to stop a train or control train speed to mitigate the risk of accidents has been raised in TSB investigation reports since 1995.TSB Railway Investigation Report R95V0174. Crews not following signal indications has been cited as a cause or contributing factor in numerous TSB investigations,TSB rail transportation safety investigation reports R24C0020, R23Q0022, R23H0006, R23D0108, R19W0002, R18D0096, R16T0162, R16E0051, R15D0118, R15V0183, R14T0294, R13C0049, R12T0038, R11E0063, R10Q0011, R10V0038, R09V0230, R07E0129, R99T0017, R98V0148, and R95V0174. and this issue has been on the TSB Watchlist since 2012.TSB Watchlist, “Following railway signal indications”, at https://www.tsb.gc.ca/eng/surveillance-watchlist/rail/2022/rail-01.html (last accessed on 08 January 2026). The TSB has issued 3 recommendations calling for additional backup safety defences (i.e., physical fail-safe train controls) in signalled territory: in 2000, 2013, and 2022 (Appendix B).

TC has been working with railway companies and industry stakeholders on potential solutions for automated train control in Canada.

In 2013, TC established the Train Control Working Group under the Advisory Council on Rail Safety to examine fail-safe train control systems. The working group studied the feasibility of implementing various levels of train control in Canada. In 2016, it published its findings and concluded that a one-size-fits-all approach would not be appropriate for Canada, given the diversity of railway operations, geographic conditions, and risk profiles. Instead, it recommended a targeted, risk-based, corridor-specific implementation of an advanced train control system as the most suitable option. Since then, TC has taken steps to lay the groundwork for this solution, referred to as enhanced train control (ETC).

In February 2022, TC published a Notice of Intent, outlining the path forward for ETC in Canada, aligned with the objectives of its strategic plan Transportation 2030 – A Strategic Plan for the Future of Transportation in Canada (Transportation 2030 strategic plan).Transport Canada, Transportation 2030 - A Strategic Plan for the Future of Transportation in Canada, at https://tc.canada.ca/en/initiatives/transportation-2030-strategic-plan-future-transportation-canada (last accessed on 08 January 2026). The notice described a high-level policy direction and the intent to develop supporting governance structures, technical specifications, and interoperability standards. However, several of these activities remain incomplete, and no binding regulatory framework, enforceable timeline, or finalized implementation plan has been established. Because of the magnitude and complexity of some of these critical activities, their implementation could take several years to complete, calling into question TC’s anticipated timeline of 2030 under its Transportation 2030 strategic plan.

Implementing an automated train control system is a complex and capital-intensive undertaking. Despite this, PTC was implemented in about 12 years, following its mandate under the Rail Safety Improvement Act of 2008. As of year-end 2020, PTC was fully operational on 57 536 route-miles of high-risk U.S. rail corridors, representing approximately 41% of the nearly 140 000 route-miles in the U.S. rail network. This includes PTC-equipped track segments operated by Canadian Class I railways in the United States: CN (3107 miles) and Canadian Pacific Railway Company, doing business as CPKC (2118 miles). By comparison, Canada’s rail network comprises about 26 000 route-miles, with 10 940 miles of main track accounting for roughly 42% of the total network.

On 17 April 2024, the TSB sent a letter to the Minister of Transport stating that, despite the calls from the TSB for additional physical fail-safe defences in signalled territory since 2000, the Canadian railway system continues to rely on administrative defences centred on compliance with rules by crews. The letter further stated that TC and the railway industry have been discussing possible solutions for ETC implementation since 2013. Given the slow pace of progress and the risks involved, the TSB strongly urged the Minister to accelerate the implementation of physical fail-safe train controls on Canada’s high-speed rail corridors and all key routes.Section 3.1 of the Rules Respecting Key Trains and Key Routes (22 August 2021, approved by Transport Canada on 22 February 2021), define a “’key route” as “any track on which, over a period of one year, is carried 10,000 or more loaded tank cars or loaded intermodal portable tanks containing dangerous goods, as defined in the Transportation of Dangerous Goods Act, 1992 or any combination thereof that includes 10,000 or more loaded tank cars and loaded intermodal portable tanks.” At the time of publication of this report, the TSB had not received a response.

Following the investigation into a 21 November 2023 occurrence in which a CN freight train collided with the tail end of a stationary commuter train, resulting in injuries to 8 passengers and 2 crew members,TSB Rail Transportation Safety Investigation Report R23D0108, published on 16 September 2025. the Board indicated that the risks associated with a failure to comply with signal indications remain high, and that it is unlikely that the level of risk will be significantly reduced before physical fail-safe defences are implemented. Pending implementation of ETC in Canada, no interim measures are required or planned by TC to reduce the risk of train collisions. Consequently, in the coming years, there will be few or no regulatory physical defences to stop a train when a crew does not follow a signal indication. The Board therefore recommended that

the Department of Transport immediately implement additional interim measures to mitigate the risks associated with train crews not complying with railway signal indications, such as collisions between trains, until adequate and permanent physical fail-safe defences are implemented.

TSB Recommendation R25-01

In December 2025, TC responded that it agreed with Recommendation R25-01 and is committed to advancing the ETC initiative. TC also submitted that, since signal adherence involves multiple risks such as human error, fatigue, and misinterpretation, it intends to advance an interim action plan until ETC is fully operational. TC will focus on revising rules to strengthen compliance, improve oversight and fatigue management to address human factors, and explore short-term technological solutions that can provide signal safety alerts to operating crews.

In its January 2026 assessment of TC’s response, the Board acknowledged TC’s stated commitment to advance ETC. However, the Board noted that TC did not commit to any specific solutions or timelines to mitigate the risks associated with train crews not complying with railway signal indications until the implementation of physical fail-safe train controls in Canada.

The Board stated that, until TC provides details of its action plan, including timelines for the implementation of additional interim measures to mitigate the risks associated with crews not following signal indications, it is unable to assess the response to Recommendation R25-01.

1.15.2.1 Industry initiatives

Beyond VIA’s cab red zone and CN’s critical focus zone, some railways have implemented additional defences that include a physical component. For example, Quebec North Shore and Labrador Railway (QNS&L) has implemented a combined administrative and physical defence system, which it calls the proximity detection device (PDD) system. The PDD system uses global positioning system (GPS) technology to determine the position, direction, and speed of locomotives and maintenance vehicles, alerting crews of approaching movements. The crews of both movements must confirm on a screen that they acknowledge the alert and must also communicate with each other by radio to verify their respective positions. A penalty brake applicationA penalty brake application refers to a controlled braking action, similar to a full service brake application but automatically initiated by a safety system (such as locomotive vigilance control, overspeed protection, or positive train control) to stop the train. will automatically occur on the controlling locomotive of a train whose crew has not acknowledged receipt of the alert. Despite this technology, the PDD system will not prevent a collision if the crew acknowledges an alert but does not reduce speed or stop the train in time.

Recent advancements in technology may offer new opportunities for additional solutions.

There is no concerted effort to standardize industry initiatives aimed at strengthening defences against crews not complying with signal indications.

1.16 TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

Not following railway signal indications is a Watchlist issue. As this occurrence demonstrates, train crews do not consistently recognize and follow railway signal indications, which poses a risk of train collisions or derailments that can have catastrophic consequences.

ACTION REQUIRED The issue of not following railway signal indications will remain on the Watchlist until there is demonstrable progress in the following key areas:

|

2.0 Analysis

The investigation found that neither the mechanical condition of passenger train P06431-29 (VIA 64) operated by VIA Rail Canada Inc. (VIA), the train handling, nor the signalling system contributed to the occurrence. Both crew members on VIA 64 were fit for duty, and no medical or physiological conditions (including fatigue) that could have affected their performance were identified. The analysis will therefore focus on the in-charge locomotive engineer’s (ICLE) perception of the signal.

2.1 The occurrence

On 29 September 2024, at approximately 1716, the VIA 64 crew was performing a shoving movement between Montréal Central Station and Victoria Bridge on the St-Hyacinthe Subdivision. The train was being handled from the lead locomotive by a locomotive engineer (LE), while an ICLE was on board the tail-end car to protect the movement. At about 1725, the train stopped on the north track, just over 300 feet from Signal 722N, which was displaying a Stop indication. Approximately 8 minutes later, the ICLE informed the LE that he was having trouble confirming the colour of the top light on Signal 722N. He asked the LE to back up 2 car lengths to get closer to the signal so he could confirm its aspect. As the tail end of the train approached Signal 722N, the ICLE perceived that the top light of the signal was yellow. He therefore interpreted the signal as displaying a permissive Medium to Stop indication. He informed the LE over the radio and asked him to continue shoving. The train passed Signal 722N, which was displaying a Stop indication, and travelled 1500 feet past the signal. As the train approached the main-track switch at the west end of Victoria Bridge, the ICLE noticed that the switch was not set for his train and immediately instructed the LE to stop the train. When the train came to a stop, the truck at the end of the tail-end car ran through the switch.

Findings as to causes and contributing factors

While doing a shoving movement, the train passed Signal 722N, which was displaying a Stop indication, and travelled 1500 feet past the signal before coming to a stop after running through a switch.

The ICLE, who was on board the tail-end car to protect the movement, had perceived that the top light of the signal had changed aspect and was yellow. He interpreted Signal 722N as permissive, and the train continued past the signal.

2.2 Signal 722N

2.2.1 Signal 722N light lenses

Signal 722N has 2 lights: the top light has a smooth lens, while the bottom light has a fluted lens.

When a light source is directed at a smooth surface, the rays reflected by that surface are parallel. This phenomenon is called specular reflection and causes all incident light to be reflected at the same angle.

On the other hand, when a light source is directed at an irregular surface (such as a fluted lens), the rays are reflected in several directions. This phenomenon, called diffuse reflection, scatters the reflected incident light.

Finding as to causes and contributing factors

The lights of Signal 722N are equipped with 2 types of lenses that reflect sunlight differently on their surface.

2.2.2 Perception of Signal 722N indication

At approximately 1725, when the train came to a stop just over 300 feet from Signal 722N, which was displaying a Stop indication, the ICLE could see and clearly observe the signal indication (red on red aspect).

While the train was stopped and the ICLE was monitoring Signal 722N for a permissive indication, the ambient light conditions changed over time due to the altitude and azimuth of the sun. Because the ICLE had trouble confirming the colour of the top light of Signal 722N, he asked the LE to back up to be closer to the signal.

At approximately 1732, as the train began to move, the sun was 10° above the horizon and directly illuminating the face of Signal 722N.

The incident sunlight was directed onto the face of the signal, which was still displaying a Stop indication (red on red aspect). As the train started moving and approached the signal, the ICLE perceived a change in the colour of the top light and determined that it had changed from red to yellow. He therefore concluded that the signal was permissive and instructed the LE to continue the shoving movement. The ICLE did not notice any further changes in the signal indication’s aspect while the signal remained in his field of vision.

According to a study, in certain conditions, a red light may appear yellowish to an observer when the incident light, reflected by the surface of the outer lens of the light, causes slight defocusing.

Finding as to causes and contributing factors

The yellow colour of the top light of Signal 722N perceived by the ICLE was likely caused by the reflection of incident sunlight on the smooth lens surface.

2.2.3 Mitigation measures

The lights of Signal 722N are equipped with extended hoods that were installed after a similar incident in 2006 to reduce the risk of incident sunlight interfering with the lenses of the lights. In this occurrence, with the sun at an altitude of 10°, its incident light likely reached the face of the smooth lens of the top light by passing under the hood.

Finding: Other

The extended hoods installed on the lights of Signal 722N did not prevent interference due to the reflection of incident sunlight on the smooth lens of the top light.

2.3 Mental model and expectations

The VIA 64 crew had been informed by the RTC that their train would be delayed because of other trains passing before theirs. The ICLE expected the signal to change to display a Medium to Stop indication to allow the train to proceed. After the ICLE saw VIA 14 passing in the opposite direction on the adjacent track, he asked the LE to back up the train by 2 car lengths to get closer to the signal so that he could confirm its indication. When the ICLE perceived a change in the colour of the top light of the signal, he concluded that the signal was displaying a Medium to Stop indication (yellow on red aspect). The ICLE then informed the LE over the radio about the permissive signal indication and asked him to continue the shoving movement eastward. Because the LE also expected the signal to change to a permissive indication, he acknowledged the information transmitted by the ICLE and assumed that it was valid. The ICLE did not notice any further changes in the signal indication’s aspect while the signal remained in his field of vision. This mental model, which was reinforced by VIA 14 passing on the adjacent track, led the crew to interpret the visual cues based on their expectations.

Finding as to causes and contributing factors

When the train stopped before Signal 722N, the crew expected this signal to change to a Medium to Stop indication. As a result, the change in colour of the top light as perceived by the ICLE was interpreted by him as valid.

2.4 VIA 64 emergency call

When the VIA 64 LE made the emergency call on the subdivision standby radio channel, a detector on the Montréal Subdivision was transmitting an automated audio message to another train on the same standby channel. This caused radio transmissions to overlap, degrading communication quality and interfering with the transmission of emergency messages. The emergency communication was not prioritized on the railway radio standby channel, contrary to the provisions of CROR Rule 125(c).

Finding as to risk

If an emergency communication is transmitted on the railway radio standby channel simultaneously with other transmissions, the overlapping messages may impair intelligibility, increasing the risk that critical information will not be communicated.

2.5 Distinctive features of railway operations in the Wellington Territory interlocking limits

The signal indications within the Wellington Territory interlocking limits only display authority to occupy the track up to the next signal and do not correspond to the authorized operating speeds in this territory.Except for Restricting indication. The maximum allowable speeds are specified in the summary bulletin or division timetable.

This inconsistency is noted in an additional instructionThis additional instruction states that the low-mast signals within the Wellington Territory interlocking limits do not display route or speed information. issued by Canadian National Railway Company (CN), the owner of the signalling infrastructure. This additional instruction addresses the outdated signalling system until it is eventually upgraded. Despite the implementation of this additional administrative defence, crews are still required by the applicable provisions of the CROR to call signals as displayed, but they must comply with the maximum speed specified in the applicable subdivision timetable.

Despite the fact that both the signal and the additional instruction are administrative defences, the application of the additional instruction relies solely on the memory and attention of crews in the absence of a direct visual cue (as in the case of a signal). In situations of high workload or unusual events, the attention of crews may be focused on other priorities, increasing the risk that this additional instruction will be forgotten or misapplied.

Finding as to risk

The implementation of additional administrative defences to clarify the indications of the outdated signalling system in the Wellington Territory interlocking limits may lead to operational errors by crews, increasing the risk of accidents in this area.

2.6 Enhanced train control

To prevent trains from passing Stop signal indications and colliding with other trains, as in this occurrence, a train control technology such as positive train control (PTC) can provide the necessary physical defences. A functioning PTC system is designed to calculate the required stopping distance and, if the crew does not apply the brakes in time, automatically enforce a penalty brake application to stop the train before it reaches the signal.

The implementation of physical fail-safe train control technologies such as PTC systems provides an extra layer of safety when operated in conjunction with existing administrative defences. However, there is no requirement to install physical fail-safe train control technologies on the Canadian rail network.

In February 2022, Transport Canada (TC) published a Notice of Intent, identifying its intention to require that the highest-risk corridors in Canada be equipped with fail-safe, automatic train protection (referred to as enhanced train control or ETC) in line with the objectives of its strategic plan titled Transportation 2030 – A Strategic Plan for the Future of Transportation in Canada. The notice described a high-level policy direction and the intent to develop supporting governance structures, technical specifications, and interoperability standards. Despite this ongoing work and the increased awareness of the need for additional backup safety defences, the TSB is not aware of any interim measures considered by TC to address the ongoing risk.

Finding as to risk

If train control systems rely only on administrative defences, potential signal recognition errors by crews will not be identified and corrected, increasing the risk of an accident.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are the factors that were found to have caused or contributed to the occurrence.

- While doing a shoving movement, the train passed Signal 722N, which was displaying a Stop indication, and travelled 1500 feet past the signal before coming to a stop after running through a switch.

- The in-charge locomotive engineer, who was on board the tail-end car to protect the movement, had perceived that the top light of the signal had changed aspect and was yellow. He interpreted Signal 722N as permissive, and the train continued past the signal.

- The lights of Signal 722N are equipped with 2 types of lenses that reflect sunlight differently on their surface.

- The yellow colour of the top light of Signal 722N perceived by the in-charge locomotive engineer was likely caused by the reflection of incident sunlight on the smooth lens surface.

- When the train stopped before Signal 722N, the crew expected this signal to change to a Medium to Stop indication. As a result, the change in colour of the top light as perceived by the in-charge locomotive engineer was interpreted by him as valid.

3.2 Findings as to risk

These are the factors in the occurrence that were found to pose a risk to the transportation system. These factors may or may not have been causal or contributing to the occurrence but could pose a risk in the future.

- If an emergency communication is transmitted on the railway radio standby channel simultaneously with other transmissions, the overlapping messages may impair intelligibility, increasing the risk that critical information will not be communicated.

- The implementation of additional administrative defences to clarify the indications of the outdated signalling system in the Wellington Territory interlocking limits may lead to operational errors by crews, increasing the risk of accidents in this area.

- If train control systems rely only on administrative defences, potential signal recognition errors by crews will not be identified and corrected, increasing the risk of an accident.

3.3 Other findings

These findings resolve an issue of controversy, identify a mitigating circumstance, or acknowledge a noteworthy element of the occurrence.

- The presence of numerous surveillance cameras in the occurrence area enabled the TSB to gather information relevant to the investigation.

- The extended hoods installed on the lights of Signal 722N did not prevent interference due to the reflection of incident sunlight on the smooth lens of the top light.

4.0 Safety action

4.1 Safety action taken

The Board is not aware of any safety action taken following this occurrence.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 21 January 2026. It was officially released on 27 January 2026.

Appendices

Appendix A – Positive train control system

Positive train control (PTC) is a federally mandated safety overlay system in the United States, designed to prevent specific high-consequence train accidents resulting from operational rule violations or human factor issues associated with signal recognition and compliance. Its development and implementation were mandated under the Rail Safety Improvement Act of 2008, following a series of catastrophic rail accidents, including a 2008 collision in Chatsworth, California, that resulted in 25 fatalities and 102 injured passengers.United States National Transportation Safety Board (NTSB), Railroad Accident Report NTSB/RAR-10/01 “Collision of Metrolink Train 111 With Union Pacific Train LOF65-12, Chatsworth, California, September 12, 2008”, at https://www.ntsb.gov/investigations/AccidentReports/Reports/RAR1001.pdf (last accessed 08 January 2026). Section 104 of the Act required the installation of interoperable PTC systems by all Class I railways and by intercity and commuter passenger rail operators, with deployment prioritized on higher-risk corridors. These included main lines transporting toxic- or poison-by-inhalation (TIH/PIH) hazardous materials, routes used for passenger or commuter service, and other lines as designated by regulation.

As of 2020, PTC systems were operational across 57 536 route-miles of U.S. rail infrastructure, including all Class I freight lines transporting 5 million gross tons or more annually, designated hazardous materials corridors, and major passenger and commuter lines. It is important to note that PTC is a United States-specific system developed to reflect the unique operational, regulatory, and risk environments of railways in the United States. While other countries employ various forms of automated train control, these systems differ in design, scope, and technical specifications.

PTC enhances safety by automatically intervening when crews fail to comply with movement authorities or speed restrictions. Its enforcement logic is intended to prevent collisions, overspeed derailments, unauthorized incursions into work zones, misaligned switch movements, and signal non-compliances due to distraction, fatigue, or reduced situational awareness. A core capability of PTC is its continuous, train-specific calculation of safe braking and warning curves, which account for locomotive control settings, train speed, train weight, track grade, track curvature, and both permanent and temporary speed restrictions, as defined in the on-board track database.

When a potential violation is detected, PTC generates predictive warnings to allow a locomotive engineer to take corrective action. If the locomotive engineer does not respond within a defined safety margin, the system initiates a penalty brake application—an automated, service-level braking intervention. If necessary, the system can escalate to an emergency brake application, applying a greater braking force to bring the train to a controlled stop in the available distance. A PTC-initiated brake application cannot be cancelled or overridden; the train must come to a full stop before the brakes can be released.

PTC does not replace conventional signal systems or movement authorities issued by rail traffic controllers; rather, it is a fail-safe safety overlay system that reinforces compliance with train control rules. Its deployment represents a significant rail safety advancement in the United States.

Appendix B – TSB recommendations for additional fail-safe train controls in signalled territory

The TSB has issued 3 recommendations calling for additional backup safety defences (i.e., physical fail-safe train controls) in signalled territory.

Recommendation R00-04

Following the investigation into the 1998 collision between 2 trains of the Canadian Pacific Railway Company near Notch Hill, British Columbia,TSB Railway Investigation Report R98V0148. the Board determined that the backup safety defences for signal indications were inadequate and recommended that

the Department of Transport and the railway industry implement additional backup safety defences to help ensure that signal indications are consistently recognized and followed.

TSB Recommendation R00‑04

The latest response from Transport Canada (TC) was assessed as Satisfactory in Part in March 2021 and the recommendation was assigned a Dormant status.TSB Recommendation R00-04: Consistent recognition of signals at https://www.tsb.gc.ca/eng/recommandations-recommendations/rail/2000/rec-r0004.html (last accessed 08 January 2026). It is linked to TSB Recommendation R13-01 and will be reassessed in accordance with that recommendation.

Recommendation R13-01

Following the investigation into a 26 February 2012 main-track derailment involving a VIA Rail Canada Inc. passenger train at Aldershot, Ontario, in which the operating crew were fatally injured and 45 people sustained various injuries,TSB Railway Investigation Report R12T0038. the TSB indicated that TC and the industry should move forward with a strategy that would prevent these types of accidents by ensuring that signals, operating speeds, and operating limits are always followed. The Board recommended that

the Department of Transport require major Canadian passenger and freight railways implement physical fail-safe train controls, beginning with Canada’s high-speed rail corridors.

TSB Recommendation R13‑01

The response from TC was most recently assessed in March 2023 to be Satisfactory in Part and the recommendation was assigned a Dormant status.TSB Recommendation R13-01: Physical fail-safe train controls at https://www.tsb.gc.ca/eng/recommandations-recommendations/rail/2013/rec-r1301.html (last accessed 08 January 2026). This recommendation is linked to TSB Recommendation R22-04 and will be reassessed in accordance with that recommendation.

Recommendation R22-04

Following an occurrence on 03 January 2019, in which 2 Canadian National Railway Company (CN) trains collided after one of the trains went past a controlled signal that displayed a Stop indication near Portage la Prairie, Manitoba,TSB Rail Transportation Safety Investigation Report R19W0002. the TSB indicated that, despite 2 TSB recommendations to TC related to automated train control dating back over 20 years, little has been done to either extend the use of positive train control (implemented in the United States) into Canada or to develop a similar form of train control in Canada. It is clear that current administrative defences for train operation are not always effective. If TC and the railway industry do not take action to implement physical fail-safe defences to reduce the consequences of inevitable human errors, the risk of collisions and derailments will persist, with a commensurate increase in risk on key routes in Canada. Therefore, the Board recommended that

the Department of Transport require major Canadian railways to expedite the implementation of physical fail-safe train controls on Canada’s high-speed rail corridors and on all key routes.

TSB Recommendation R22-04

In its December 2024 response, TC indicated that it has made significant progress in developing its corridor risk evaluation methodology that will guide the application of enhanced train control (ETC) on Canada’s rail network. It also informed the TSB that it continues to engage with industry and other stakeholders to finalize the methodology. Consultations are underway to assess the cumulative impacts of these requirements on regulated parties. Regulatory drafting is planned for 2025, with an anticipated timeline for publication in the Canada Gazette, Part I in 2026. Timelines for implementation of ETC will be determined when the regulations are developed.

In its March 2025 assessment of TC’s response, the Board recognized that developing and implementing ETC is a complex undertaking requiring significant investment and that TC and the industry have taken steps to address this. However, the Board noted that the corridor risk assessment methodology has not yet been completed, which calls into question the timing of the implementation of a fail-safe train control system. Given the risks to life, property, and the environment, the Board urged TC and the rail industry to expedite the implementation of physical fail-safe train control technologies on Canada’s high-speed rail corridors and on all key routes across the country. Although the Board believes that the response to Recommendation R22-04 indicates satisfactory intent,TSB Recommendation R22-04: Enhanced train control for key routes, at https://www.tsb.gc.ca/eng/recommandations-recommendations/rail/2022/rec-r2204.html (last accessed 08 January 2026). if further delays in implementing the recommendation occur, this assessment could be downgraded in the future.

In September 2025, as part of its investigation into the 21 November 2023 occurrence in which a CN freight train collided with the tail end of a stationary commuter train, resulting in injuries to 8 passengers and 2 crew members,TSB Rail Transportation Safety Investigation Report R23D0108. the Board reiterated Recommendation R22-04.