Accidental release of free-fall lifeboat and crew injury

Bulk carrier Golden Zhejiang

Trincomali Channel, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 02 September 2023, the bulk carrier Golden Zhejiang was at anchor in Trincomali Channel, British Columbia when the second and fourth engineers were carrying out a weekly safety check of the free-fall lifeboat. During the safety check, the second engineer encountered an issue while testing the steering from inside the lifeboat. While he was attempting to troubleshoot this issue, the main release mechanism was inadvertently activated. The lifeboat dropped into the water with the second engineer inside, and he was seriously injured. No pollution was reported.

International Maritime Organisation Classification: Marine Casualty

1.0 Factual information

1.1 Particulars of the vessel

Name | Golden Zhejiang |

|---|---|

Flag | Hong Kong |

Vessel type | Bulk carrier |

International Maritime Organization (IMO) number | 9443619 |

Gross tonnage | 92270 |

Length overall | 292 m |

Moulded breadth | 45 m |

Moulded depth | 25 m |

Year built | 2010 |

Builder | Zhoushan Jinhaiwan Shipyard Co. Ltd., China |

Crew complement | 22 |

Registered owner | SFL Zhejiang Inc. |

Disponent owner* | Golden Ocean Group Ltd. |

Technical ship manager and operator | Columbia Shipmanagement Ltd. |

Classification society | American Bureau of Shipping |

Issuing authority for International Safety Management certification | DNV for interim document of compliance American Bureau of Shipping for interim safety management certificate |

*A disponent owner is a person or company that has the possession and benefit of the vessel. (Source: Institute of Chartered Shipbrokers, Legal Principles in Shipping Business (2016)).

1.2 Description of the vessel

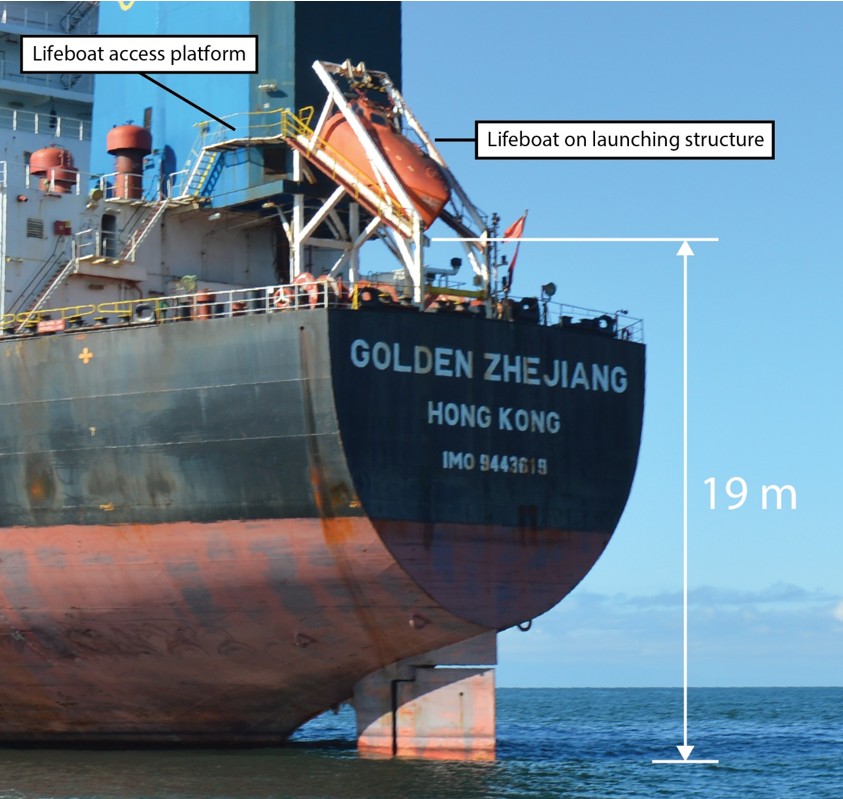

The Golden Zhejiang (Figure 1) is a bulk carrier built in 2010. The vessel is propelled by a 16 MW diesel engine and is equipped with the navigational equipment and life-saving appliances required under the International Convention for the Safety of Life at SeaInternational Maritime Organization, International Convention for the Safety of Life at Sea (SOLAS) (1974, last amended 2020). (SOLAS).

1.2.1 Free-fall lifeboat

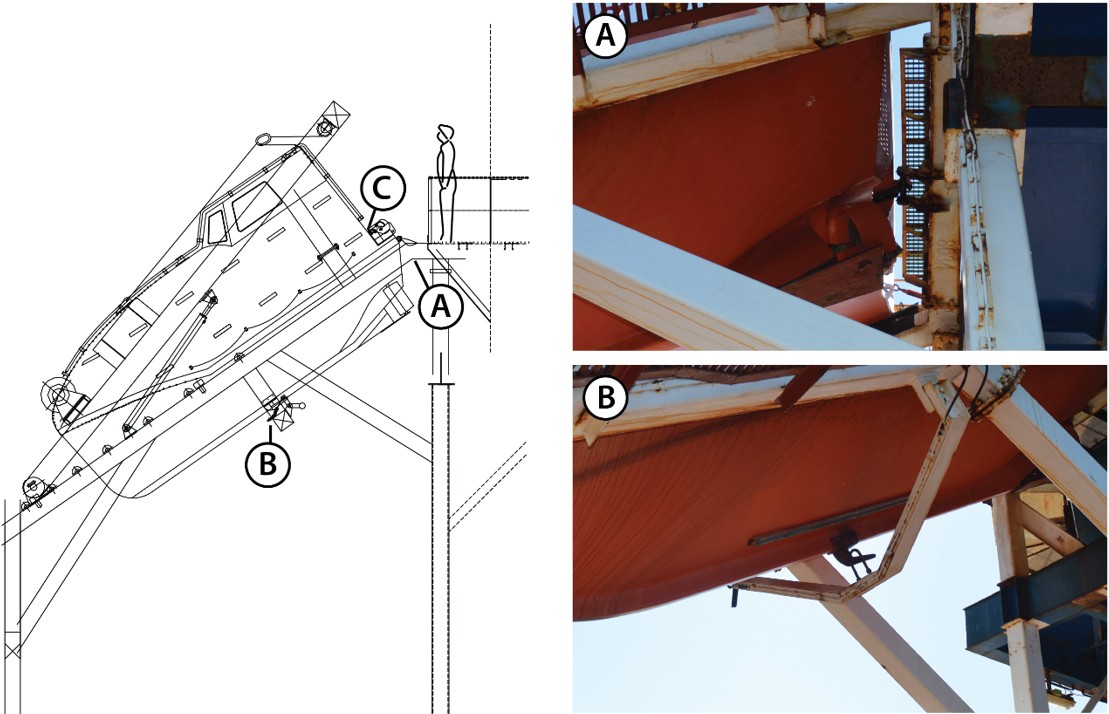

The Golden Zhejiang is equipped with a free-fall lifeboat. The lifeboat is stowed on a launching structure located at the stern (Figure 2). On the day of the occurrence, the lifeboat was about 19 metres above the water surface. The lifeboat is positioned with its bow down at an angle of approximately 30° toward the vessel’s stern. It weighs 4400 kg when empty and its length overall is 7.5 m.

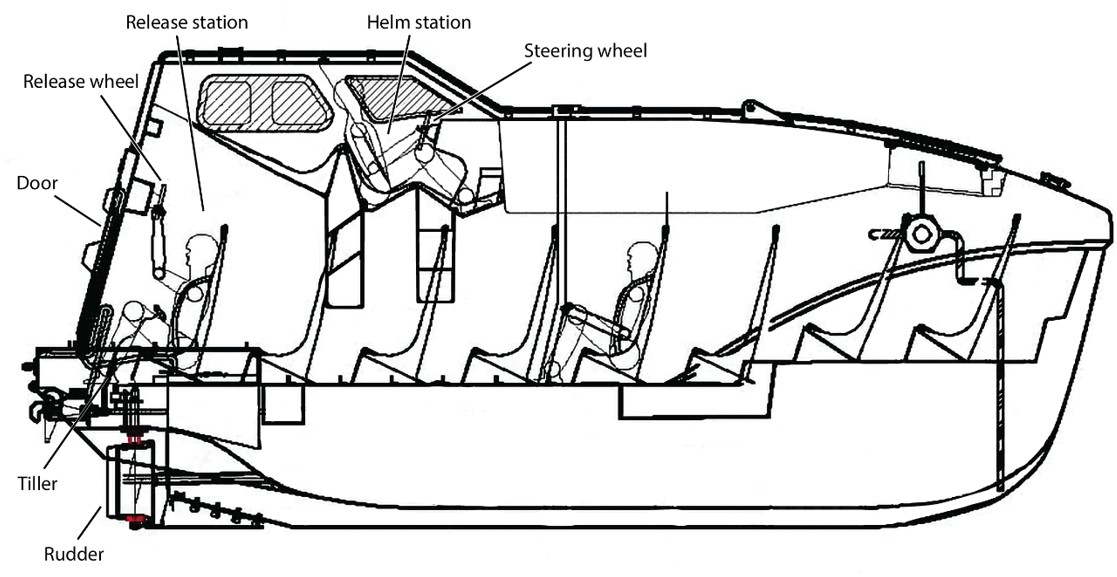

The lifeboat has 29 seats on the main deck and 1 helm station above the main deck (Figure 3). Each seat is fitted with a restraining harness. Entry into the lifeboat is from the lifeboat access platform and through the lifeboat’s aft door.

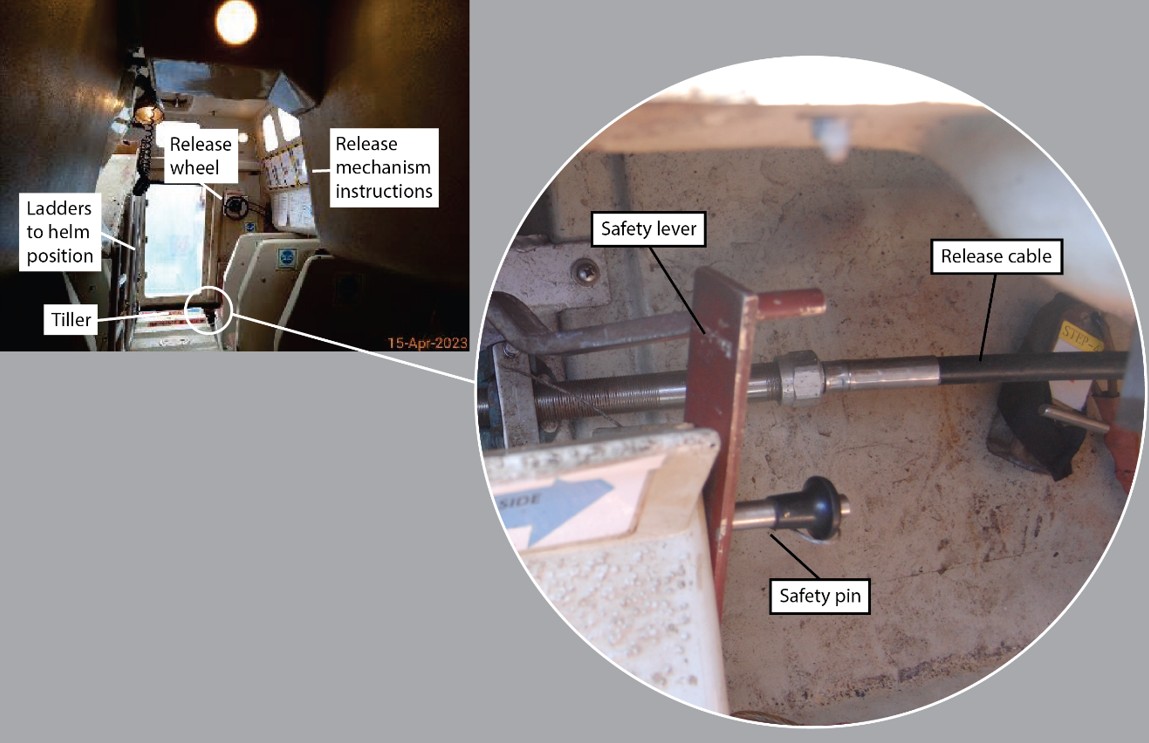

The first seat on the lifeboat’s port side is the release station, with the release wheel in front of the seat (Figure 4) and the safety pin and safety lever to 1 side of the seat (Figure 4, inset). The helm station is accessed by ladders slightly forward and on the lifeboat’s starboard side.

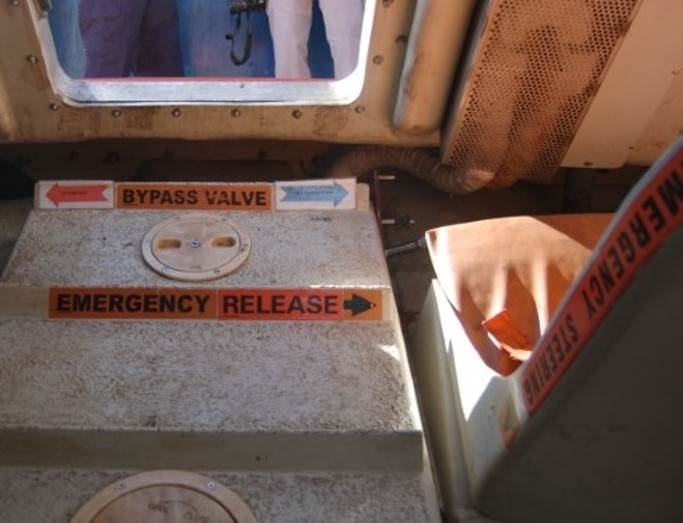

The lifeboat’s emergency steering is immediately in front of the door under a deck plate. The emergency steering is operated with a tiller, as is typical (Figure 5). The second engineer was familiar with this arrangement from his general experience with lifeboats on other vessels.

1.3 History of the occurrence

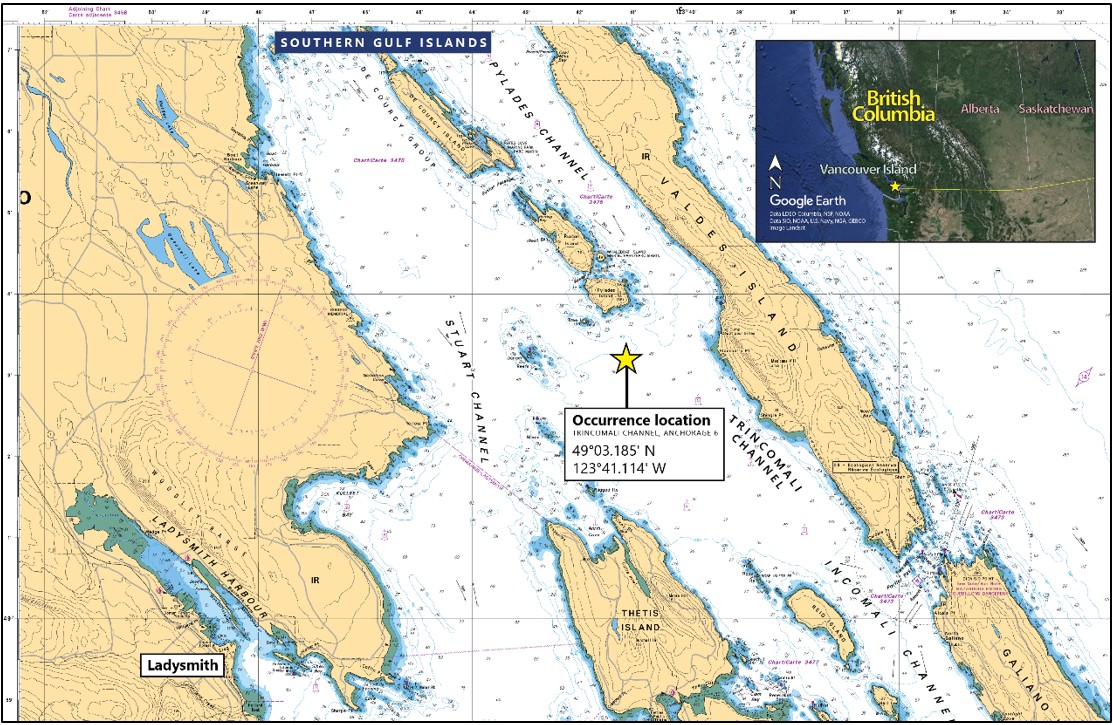

On 02 September 2023, the Golden Zhejiang was anchored in Trincomali Channel (Figure 6), British Columbia, awaiting loading.

At approximately 0730,All times are Pacific Daylight Time (Coordinated Universal Time minus 7 hours) unless otherwise indicated. the engine room team reviewed the day’s planned work in a morning meeting. After the meeting, the second engineer and the fourth engineer donned their personal protective equipment and began the weekly safety checks.In this report, “safety check” is used for all checks done by members of the crew, and “inspection” is used for all checks conducted by trained service technicians or other external authorities. They started and stopped the emergency pumps in the engine room and then moved to the deck and checked the vent flaps for correct operation. At approximately 0900, they opened the lifeboat for a few minutes to air it out and then entered it to begin the lifeboat safety check. The second engineer started the engine and checked the inside lights. Next, the second engineer asked the fourth engineer to exit the lifeboat and to check exterior lights from the outside and monitor the rudder movement. The fourth engineer exited the lifeboat and stood on the lifeboat access platform to monitor the lights and rudder as instructed.

The fourth engineer observed that the rudder was hard to port. At the same time, the second engineer was trying to turn the steering wheel at the helm station, but the rudder remained hard to port. To troubleshoot the steering problem, the second engineer moved from the helm station toward the stern of the lifeboat, where the emergency steering tiller was located. The fourth engineer could see the second engineer until the second engineer moved to the port side of the lifeboat, just inside the door. Immediately afterward, at approximately 0913, the lifeboat’s securing cables parted and the lifeboat fell in the water with the second engineer inside.

The fourth engineer notified the third engineer, who was in the control room, of a person overboard. The third engineer then called the third officer on the bridge to notify him of a person overboard. At 0914, the bridge broadcast the alarm for a person overboard emergency. At 0920, the Golden Zhejiang’s rescue boat was launched and the second officer called both Victoria Marine Communications and Traffic Services (MCTS) and 911.

The rescue boat crew found the second engineer unconscious inside the lifeboat, with head and other injuries, and provided first aid treatment immediately. At approximately 1015, after trying unsuccessfully to resolve the lifeboat steering issue, the crew towed the lifeboat alongside the Golden Zhejiang. At 1035, the Canadian Coast Guard hovercraft Moytel and the fast rescue craft Ganges 1 arrived with paramedics. The second engineer was transferred to hospital. He sustained permanent, life-changing injuries and partial memory loss.

1.4 Environmental conditions

At the time of the occurrence, the sky was clear and the wind was from the north at about 10 knots. The tide was ebbing and the sea was calm. The air temperature was approximately 21 ℃.

1.5 Vessel certification

The Golden Zhejiang was crewed, equipped, and certified in accordance with International Maritime Organization (IMO) requirements. The vessel held an interim safety management certificate (SMC) from the American Bureau of Shipping, and Columbia Shipmanagement Ltd. (CSM), the operator, held an interim document of compliance from DNV. Both were issued in May 2023 and were valid for 6 months.

1.6 Personnel certification, experience, and training

The master held a Master Mariner certificate of competency. He had nearly 40 years of seagoing experience and had worked as a master since 2006. This was his 2nd contract working on vessels operated by CSM.

The chief officer held a Master Mariner certificate of competency. He had 20 years of seagoing experience and had been a chief officer since 2019. He had worked on ships operated by CSM for 16 years.

The chief engineer held a First-class Engineer certificate of competency. He had about 25 years of seagoing experience and had been a chief engineer since 2011. This was his 1st contract working on ships operated by CSM.

The second engineer held a First-class Engineer certificate of competency. He had about 24 years of seagoing experience and had been a second engineer since 2013. He had worked on ships operated by CSM for almost 2 years.

The fourth engineer held a Third-class Engineer certificate of competency. He had 3 years of seagoing experience. This was his 1st contract working on ships operated by CSM.

1.7 Vessel management

Large commercial vessels, such as the Golden Zhejiang, are often managed by technical management companies. The technical management company manages the operation of the vessel, including crewing, maintenance, and day-to-day operation.Cargo operations and other commercial operations may be managed by a disponent owner or management company. The technical management company also manages all duties and responsibilities required by SOLAS, class, and flag state. Crew members typically work on individual contracts for a number of months and are likely to work on different vessels that are managed by the same company.

Industry practice is to assign 1 or more persons on the shore staff as technical managers to oversee the technical needs of 1 or more vessels. While members of the shore staff often hold certification as an engineering or deck officer, there is no requirement for them to do so. Shore staff typically hold permanent positions or at least have longer-term contracts than crew.

When a commercial vessel changes ownership or management and no major problems have been identified during the changeover, it typically enters full operations right away.In 2013, the IMO considered a proposal from Canada and the Republic of Korea to amend the ISM Code to require the transfer of maintenance and failure history when vessels change ownership. The sub-committee agreed in principle with the need for continuity, but the change was not made because of practical considerations related to implementation. (IMO (STW 44/10/1), “Revision of the ISM Code to include transfer of ship maintenance and failure records,” 22 February 2013.)

In May 2023, CSM took over technical management of the Golden Zhejiang and a completely new crew joined the vessel.

At the time of the occurrence, the master had been on the vessel for 45 days and was completing a 4-month contract. The chief engineer was finishing a 4-month contract and had been on the vessel for 122 days. The chief officer and the second engineer had been on the vessel for 12 days. The majority of the remaining officers and crew had been on the vessel for over 3 months.

Columbia Shipmanagement Ltd. manages over 400 vessels from 15 different management offices in various countries. The Cyprus office manages approximately 106 vessels, including the Golden Zhejiang. The Cyprus office holds 10 documents of compliance (DOCs), all issued by DNV, covering different flag states and vessel types.

1.7.1 Division of responsibility on board

Responsibility for on-board technical operations, safety checks, and maintenance, including maintenance of the life-saving appliances, is divided between the deck officers and the engine room officers. For example, technical matters for all equipment, such as defect reporting and repairs, are the responsibility of the chief engineer, and deck machinery, cargo compartments, and deck gear in general are the responsibility of the chief officer.

With respect to the free-fall lifeboat on the Golden Zhejiang, operation, safety training, and regulatory compliance were the responsibility of the chief officer. Maintenance requirements for the lifeboat, such as the maintenance of its engine, were the responsibility of the chief engineer. On the vessel, the chief engineer had delegated the responsibility for the lifeboat to the second engineer.

With respect to safety, the master, chief engineer, chief officer, and second engineer were all identified in the safety management system (SMS) as responsible for implementing the SMS; improving procedures; and reviewing and improving the SMS. For more information about the SMS and the SMS documentation, see section 1.8.3, The CSM safety management system. The chief officer had the role of safety officer. The role of safety officer was described in the General Operations Manual and includes ensuring

- a robust safety and health culture with the aim to prevent accidents,

[…]

- regular preventative maintenance, inspection, and testing of all safety equipment, and

[…]

- that corrective and preventative actions are implemented timely [sic] and effectively.Columbia Shipmanagement Ltd., 2.3.1 “The Ship Safety Officer,” Quality, Safety and Health, Environmental and Energy Management System: General Operations Manual (07 September 2023). All the sections of this document cited in the present report were valid at the time of the occurrence.

Communication with the shore staff was primarily the master’s responsibility, except for engine room maintenance, where the chief engineer communicated directly with the shore-based technical manager.

1.8 Free-fall lifeboats

Free-fall lifeboats are closed lifeboats, designed to slide from a launching structure on the stern of a vessel without any apparatus to lower the lifeboat while abandoning ship. The starting height above the water gives a free-fall lifeboat considerable speed when it is released; because of the lifeboat’s speed and the angle of the launching structure ramp, the lifeboat drops into the water well away from the vessel. A davit or other apparatus is used to launch and retrieve the lifeboat for drills, testing and servicing, or other reasons. However, unlike davit-launched lifeboats, free-fall lifeboats do not need lifeboat davits for launching in case of emergency.

Free-fall lifeboats are secured to the launching structure at a single point. At this point, they are held to the launching structure by a release hook (Figure 7), which is a component of the release mechanism.

When a vessel is in operation, a free-fall lifeboat should be protected against movement from the vessel’s motion. It should also be held in position on the launching ramp in such a way that it can still be released in an emergency.

Given the height at which lifeboats are stored, the consequences of an accidental release may be serious. When a vessel is not in operation, the lifeboat should be secured against accidental release.

The Golden Zhejiang’s lifeboat (model GES-25 MKII, serial number 23232) was installed in 2010. It was manufactured in 2010 by Norsafe; Viking Life-Saving Equipment acquired Norsafe in 2018.Between 2012 and 2017, in the last 5 years before the model was discontinued in 2018, 161 lifeboats of this model, with the same release system, were produced by Viking Norsafe.

1.8.1 Securing arrangements at sea

When the Golden Zhejiang was at sea, the lifeboat was secured in the following ways (Figure 8):

- It was held to the launching structure with the release hook.

- It was protected against movement caused by the vessel’s motion by a strap over the stern.

- It was held in position on the launching ramp by a keel hook.

1.8.2 Securing arrangements for maintenance

Securing arrangements for maintenance should protect against accidental release. The IMO has issued a number of circulars related to securing arrangements for lifeboats designed to be lowered with people on board (on-load release mechanisms):

- MSC.1/Circ.1327 (2009) “Guidelines for the Fitting and Use of Fall Preventer Devices (FPDs)” provides an “interim risk mitigation measure […] pending the wide implementation of improved hook designs with enhanced safety features.”

- MSC.1/Circ.1392 (2011, updated Oct 2015) “Guidelines for Evaluation and Replacement of Lifeboat Release and Retrieval Systems” indicates that fall preventer devices should be used until the lifeboat release and retrieval system is compliant with the International Life-Saving Appliances (LSA) Code paragraphs 4.4.7.6.4 and 4.4.7.6.6. These paragraphs of the LSA Code do not apply to free-fall lifeboats.

The LSA Code paragraph 4.4.7.6 specifies extensive requirements of release mechanisms for “every lifeboat to be launched by a fall or falls, except a free-fall lifeboat.” SOLAS Ch II regulation 1.5 indicates that all lifeboat on-load release mechanisms that do not comply with LSA Code paragraphs 4.4.7.6.4 to 4.4.7.6.6 must be replaced with equipment that does comply by 01 July 2019, noting that these paragraphs do not apply to free-fall lifeboats.

Finding: Other

There are no international guidance documents or regulations for safely securing free-fall lifeboats during maintenance and service.

When the Golden Zhejiang was at anchor, in addition to the at-sea securing arrangements, the lifeboat was lashed to the launching structure by 2 cables (securing cables), 1 on each side of the lifeboat (Figure 9). At the time of the occurrence, the cables were in place.

The investigation could not obtain any load test certificates, purchase records, maintenance documents, or other certifications for these 2 cables. For other load-bearing cables on the Golden Zhejiang, the safety officer maintained such records. The securing cables were not listed in the deck equipment certifications, where items such as gangway, crane, and davit wires were listed.

The TSB laboratory examined the cables used to secure the lifeboat (Figure 10) and performed calculations to estimate the dynamic load that would have been exerted on the 2 cables when the lifeboat was released. It was concluded that as installed, with visible slack, this kind of cable was inadequate for securing the lifeboat. It was also concluded that the cables failed likely because of the high shock loads to which they were subjected.

In the 2008 version of the lifeboat manual held on board, the lifeboat manufacturer recommended the use of turnbuckles on both sides of the lifeboat (Figure 11) to secure the lifeboat to the vessel during free-fall training. The 2020 version of the manual added that the turnbuckles should also be used for maintenance. At the time of the occurrence, CSM was not aware of or in possession of the 2020 version of the manual, and such turnbuckles were not in use on the Golden Zhejiang lifeboat.

1.8.3 Release mechanisms

The release hook of a free-fall lifeboat may be released by a mechanical or hydraulic release mechanism. Norsafe stopped producing GES25 lifeboats with the NFFH-50 wheel-shaped mechanical release mechanism in 2017; after this point, all of the GES25 lifeboats were delivered with the hydraulic HRS10 release mechanism and the release lever was located at the helm station. The second engineer was familiar with the type of release mechanism operated by a lever located at the helm station.

The Golden Zhejiang’s free-fall lifeboat was fitted with a NFFH-50 mechanical release mechanism. The release hook was operated by a cable that was normally connected to the release wheel at a station just inside the lifeboat’s door (Figure 4). When the release mechanism was set, the cable had some slack (2 turns of the release wheel). To protect against accidental use of the release mechanism, a safety pin was set in a safety lever and the lever prevented the cable from operating (Figure 4, inset). The lifeboat also had an emergency release mechanism that bypassed the emergency release wheel whereby the cable was directly operated using a pull handle.

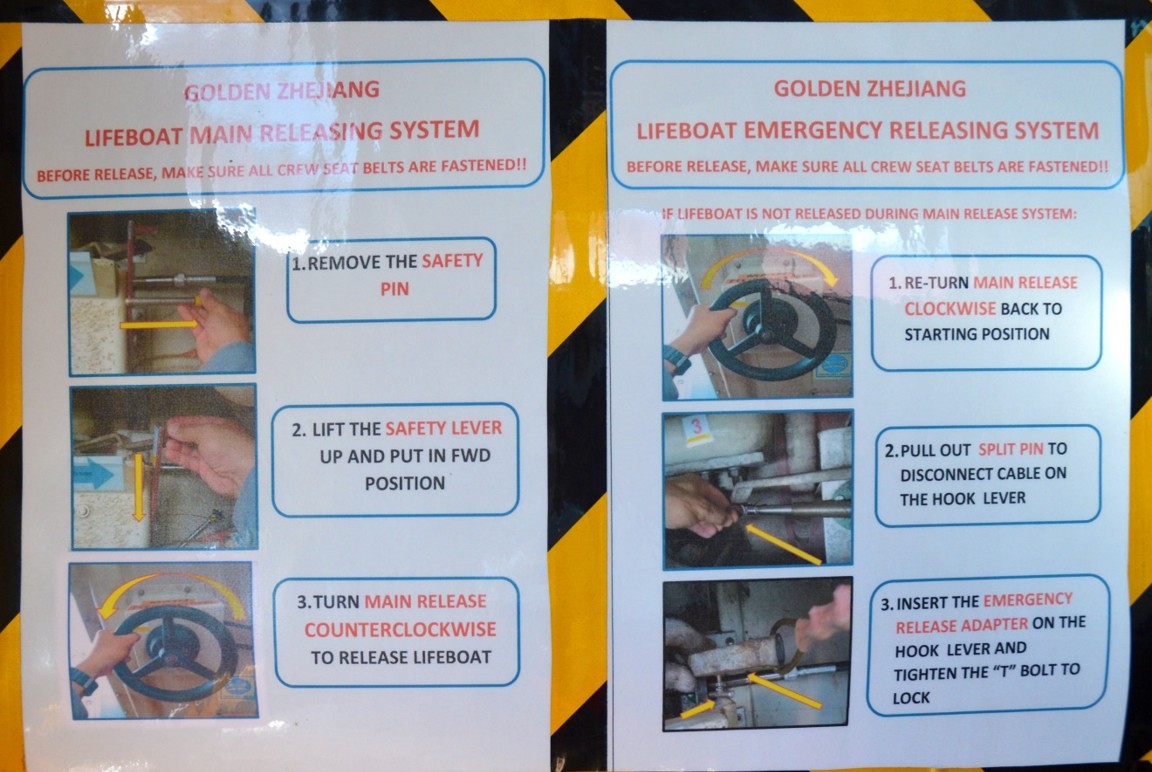

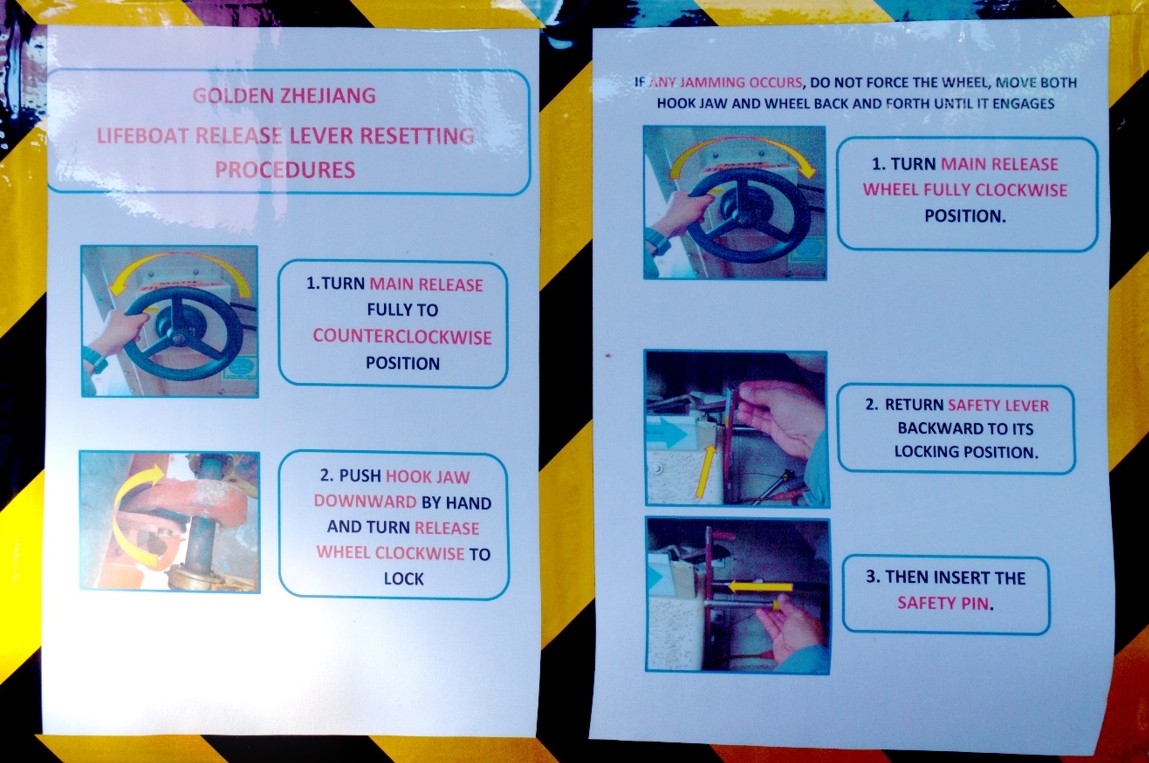

To release the Golden Zhejiang’s lifeboat using the main release mechanism, the operator has to first remove the safety pin, then lift the safety lever up and put it into a forward position, and finally turn the release wheel 2 complete turns counterclockwise. The release wheel pulls on the cable, allowing the release hook to open. To reset the release mechanism, these 3 steps must be done in reverse.

Two sets of instructions were posted on the port side wall at the release station. The original instructions were printed in black on a white background, and the numbers on the controls, such as the “2” on the release wheel, corresponded to these instructions. Another set of slightly different instructions (Appendix B) was posted on the same wall, above the original instructions. These instructions described the main release, the emergency release, and the steps to reset the mechanism after release.

In the Golden Zhejiang’s lifeboat, the release wheel (Figure 12) was identical to the steering wheel at the helm station. In 2012, the IMO published guidelinesInternational Maritime Organization, MSC. 1/Circ. 1419, Guidelines for the Standardization of Lifeboat Control Arrangements (13 June 2012). that recommended that the lifeboat release control should be on the right side of the helm and have a shape and operation that cannot be easily confused with other controls.It is highly unusual for a lifeboat or other boat of a similar size to have 2 steering stations. Like the IMO circulars about fall preventer devices for securing lifeboats, these guidelines excluded free-fall lifeboats.

The IMO has identified release mechanisms as a common factor in lifeboat accidents.International Maritime Organization, MSC/Circ. 1206, Measures to Prevent Accidents with Lifeboats (26 May 2006). In 2015, the Australian Transport Safety Bureau released a report on an unintentional free-fall lifeboat release where the release mechanism was not properly reset from the previous lifeboat release while the vessel was in port.Australian Transport Safety Bureau (20 May 2015), “Unintentional release of the freefall lifeboat from Aquarosa, Indian Ocean on 1 March 2014,” 307-MO-2014-002. The unintentional release occurred 4 days into the ship’s voyage, while the engineers were conducting maintenance on the lifeboat. This unintentional release also occurred partly due to the failure of similarly designed securing cables.

The Golden Zhejiang’s crew reported that after the occurrence, the lifeboat was found with the safety pin removed and the safety lever in the forward position. The investigation found no records confirming that the release mechanism was in place beyond general reference in the weekly safety checks and the monthly safety meeting minutes. The last recorded release of the lifeboat was under the previous owner (March 2023), and the investigation found no record the safety pin and the safety lever had been reset according to procedures.

1.8.4 Signage and labelling

Clear and effective signage and labelling are crucial for emergency situations, conducting drills, and performing safety checks and maintenance. Signage and labelling are especially important for emergency equipment, which may not be regularly used, may need to be used by crew members who are unfamiliar with the equipment, and is likely to be used in stressful situations where cognitive demands are high. Effective signage and labelling helps crew members to identify components and minimizes confusion and potentially dangerous actions.

In 2012, in response to continued accidents involving lifeboat controls, the IMO published additional guidance related to the human factors engineering design of lifeboat release mechanisms, including the following:

- The release control should be red in colour, and the area immediately surrounding the control should be a sharply contrasting light colour. No other control, handle or lever should be red.

- The release control is pulled, pushed, or rotated, etc., to open the hook. The control should operate in a logical manner and be prominently marked with an arrow to show direction of movement of the control which will cause the hook to open.

- The release control and its components should be clearly labelled to aid understanding and operation.

- The release control should have a shape, location and operation so that it cannot be easily confused with any other control.International Maritime Organization, MSC. 1/Circ. 1419, Guidelines for the Standardization of Lifeboat Control Arrangements (13 June 2012).

However, this paragraph of the LSA Code excludes free-fall lifeboats.

When the Golden Zhejiang’s lifeboat was installed in 2010, the lifeboat release system was requiredInternational Maritime Organization, International Life-Saving Appliances Code (2008), paragraphs 4.7.6.1 and 4.7.6.3. to be operated from inside the lifeboat and marked in a contrasting colour from the surroundings. Typically, the manufacturer supplies a labelled lifeboat. However, labelling and signage may be removed then reapplied over time, or additional signage may be added by the crew.

At the time of the occurrence, the labelling inside the lifeboat at the release station was missing or unclear:

- The seat at the release station was labelled “emergency steering” with an arrow pointing down. There was also an emergency release label on the deck between the seats, with an arrow pointing at this seat (Figure 13).

- The release wheel label was located on top of the release wheel housing, and was not visible to a person seated at the labelled position.

- The 2 sets of main release instructions were positioned high on the port wall of the lifeboat and were not immediately visible to a person seated at the release wheel position (Appendix B).

- The step number 2 on the housing of the release wheel did not correspond to the steps in the most prominent set of instructions for release.

- Neither the safety pin, safety lever, nor the emergency release cable handle for the release mechanism were labelled individually.

- The labels for the release mechanism were the same colours and font as the labels for other controls and positions throughout the lifeboat.

There were no indications of any deficiencies related to labels and signage on any inspection reports reviewed by the investigation (class society audit reports, port state control inspection reports, lifeboat service reports). However, there were no IMO guidance documents or regulations against which to assess compliance or deficiencies.

Other TSB investigations,Marine Investigation Report M14C0045 and Aviation Investigation Report A06C0204. have found signage that was unclear and confusing. International investigationsU.S. National Transportation Safety Board Marine Accident Reports (NTSB/MAR-98/01) Allision of the Liberian Freighter Bright Field with the Poydras Street Wharf, Riverwalk Marketplace and New Orleans Hilton Hotel. and (NTSB/MAB1740) Sinking of Motor Vessel Exito.,United Kingdom Marine Accident Investigation Branch Report, Inadvertent launching of lifeboat from coastal products tanker Solent Fisher (29 November 2005). have also identified missing signage, non-ideal locations, misleading or incorrect instructions, and generic signage and instructions as contributing factors in the occurrences.

1.8.5 Inspections and safety checks

SOLAS regulations define requirements for free-fall lifeboat safety checks and inspections:

- A weekly safety check must be conducted and reported for all survival craft and “shall include, but is not limited to, the condition of hooks, their attachment to the lifeboat and the on-load release gear being properly and completely reset.”International Maritime Organization, International Convention for the Safety of Life at Sea (SOLAS), 1974 (as amended December 2000), Chapter III, Regulation 20, Paragraph 6.

- Certified personnel from the manufacturer or from an authorized service provider must inspect the lifeboat and perform an operational test annually.International Maritime Organization, Resolution MSC.402(96), Requirements for Maintenance, Thorough Examination, Operational Testing, Overhaul and Repair of Lifeboats and Rescue Boats, Launching Appliances and Release Gear (in force as of 01 January 2020), section 6.2.

- Lifeboats must also undergo more comprehensive operational testing and inspections every 5 years.Ibid., section 6.3.

The primary purpose of these safety checks and inspections is to ensure that the lifeboats will function in an abandon ship situation.

Additional requirements from the IMO related to free-fall lifeboat maintenance, examination, and testing are indicated in resolution MSC.402(96) dated 19 May 2016. Among other requirements, the IMO states that inspections must be carried out according to the documentation provided by the manufacturer and that maintenance manuals and associated technical documentation must be kept up to date by the vessel operator.Ibid, subsections 6.1.1 and 6.1.3.

The Golden Zhejiang crew carried out weekly safety checks of the lifeboat, as described in the SMS manuals. These checks were divided between the deck crew and the engine room crew. The planned maintenance system records show that from July 2023 until the time of the occurrence, the weekly safety checks of the lifeboat were signed by a deck officer. These records show that the safety checks were done but do not give additional detail, so it is unclear whether the safety checks met the SOLAS requirements. Additionally, the planned maintenance system records for the weekly safety check pointed to a more general circularInternational Maritime Organization, MSC/Circ. 1206/Rev.1, Measures to Prevent Accidents with Lifeboats (11 June 2009). and not directly to the SOLAS requirements. No deficiencies were recorded. The safety officer carried out monthly safety checks in preparation for port state inspections. The records for these safety checks showed a greater level of detail. These records identified defects that were not recorded in the planned maintenance system, such as the hydraulic leak on the davit, which was first reported at the safety meeting held on 31 August 2023.

In September 2022, the lifeboat manufacturer carried out an annual safety inspection (thorough examinationInternational Maritime Organization, International Convention for the Safety of Life at Sea (SOLAS), 1974 (as amended December 2000), Chapter III, Regulation 20.). The inspection included the release gear, maintenance pendants, davit, and launching structure. The inspection found all components to be in acceptable condition.

The most recent 5-year inspection, carried out by the lifeboat manufacturer in 2020, found that all normal maintenance procedures had been carried out and all relevant certificates for the lifeboat, winch, davit, hooks, and fall wires were in order. No deficiencies were recorded, and no rectifications were required. Specifically, no deficiencies were recorded related to the release mechanism, to the method of securing the lifeboat, or to the markings and decals.

In the same year, ABS also conducted a 5-year periodic examination and testing of the launching structure and release mechanisms of the Golden Zhejiang lifeboat. No deficiencies were recorded.

1.8.6 Technical documentation requirements

SOLAS regulations define requirements for instructions for inspections and maintenance.Ibid., Regulation 36. As well, IMO resolution MSC.402(96) provides guidance to vessel owners, equipment manufacturers, and authorized service providers, stating that vessel owners should keep technical documentation up to date, taking into account relevant information available from the manufacturer.International Maritime Organization, Resolution MSC.402(96), Requirements for Maintenance, Thorough Examination, Operational Testing, Overhaul and Repair of Lifeboats and Rescue Boats, Launching Appliances and Release Gear (in force as of 01 January 2020), subsection 6.1.3.,International Maritime Organization, International Management Code for the Safe Operation of Ships and for Pollution Prevention (International Safety Management (ISM) Code), 1993 (as amended 2013), section 11. Although lifeboat service technicians must be certified, the vessel owner or operator is not obliged to maintain a relationship with the lifeboat manufacturer for service or support after the initial installation.

The original version of the lifeboat manual (2008) was on board the Golden Zhejiang. The version of the manufacturer’s Operations and Maintenance Manual on board the vessel contained instructions for resetting the release mechanism after a drill or release, and specified detailed weekly and monthly maintenance tasks for the crew to complete (see Appendix A). The manual also contained a monthly checklist that included a check of the release mechanism (among other things, verification that the release hook was engaged, the release safety pin and safety lever were in place, and the release wheel had been turned to return slack to the cable). The monthly checklist also specified that the rudder should be pointing straight.

A 2020 version of the manual included changes following IMO guidelines for making the manuals more user-friendly for seafarers, to help address the causes identified by IMO for lifeboat accidents, including lack of understanding of release mechanisms.International Maritime Organization, MSC.1/Circ1205/Rev.1, Revised Guidelines for Developing Operations and Maintenance Manuals for Lifeboat Systems (26 June 2019). This version of the manual was not on board.

1.9 Awareness of lifeboat safety

International and national organizations have recognized the high number of accidents related to lifeboats in which crew members were injured or died and have responded with reports and information, guidance, and regulation.

In 2023, the Bahamas Maritime Authority issued a marine noticeBahamas Maritime Authority, Marine Notice 82, version 11 (30 October 2023), Lifeboat Safety, at https://www.bahamasmaritime.com/wp-content/uploads/2023/10/MN082-Lifeboat-Safety.pdf (last accessed 17 October 2025). emphasizing the importance of drill quality, training, and familiarization for lifeboat safety and indicating that inadvertent operation of the release mechanism was a common cause of accidents. Also in 2023, China recommended that the IMO’s sub-committee on implementation of IMO instruments consider the safety of life-saving appliances, especially with respect to lifeboat slings (cables).International Maritime Organization, Sub-committee on Implementation of IMO Instruments, 9th session III 9/4/4 (11 May 2023), Lessons learned and safety issues identified from the analysis of marine safety investigation reports, Re-analysis of safety risks and proposed countermeasures regarding accidents of lifeboat slings.

The issue of inadvertent release of free-fall lifeboats was raised in a 2024 paper submitted to the IMO by InterManager.International Maritime Organization, Sub-committee on Implementation of IMO Instruments, 10th session, III 10/INF.17 (13 May 2024), Lessons learned and safety issues identified from the analysis of marine safety investigation reports – Identified issues relating to the implementation of IMO instruments from the analysis of data, Analysis of accidents involving survival and rescue craft onboard ships. The authors found that 206 lifeboat accidents reported between 1980 and 2024 listed the release mechanism as the immediate cause of the accident. In this report, causes related to the release mechanism include “complexities or unfamiliarity with the handling of securing hooks, and the operation of the release mechanism in enclosed lifeboats.” InterManager updates its lifeboat safety statistics monthly. In these statistics, both release mechanisms and chains or links that break are identified as common causes for lifeboat accidents.InterManager, Safety Statistics, at https://www.intermanager.org/safety-statistics/ (last accessed 20 October 2025).

Since 2002, the IMO has issued and revised a number of circulars about different aspects of safety during lifeboat maintenance and drills (Appendix C). The IMO distributes circulars to flag state administrations with the intention that the information will be distributed widely to vessel owners, operators, builders, designers, and other parties.

1.10 Safety in maritime operations

Regardless of the division of responsibility, safety in maritime operations is the responsibility of everyone who sets regulatory and other requirements for a vessel and everyone who is involved in operation, management, verification, and support of the vessel, from crew to shore staff to regulators to inspectors. Safety is more than the absence of accidents and incidents or compliance with regulations, and it depends on a mature safety culture and documented, systematic processes.

SMS is an internationally recognized framework that allows companies to identify hazards, manage risks, and make operations safer—ideally before an accident occurs. An SMS is a documented, systematic approach to assessing and managing operational risk that provides individuals at all levels of an organization with the tools they need to make sound decisions in routine and emergency operations. The IMO maintains regulations and codes for safety and safety management such as SOLAS, the International Safety Management (ISM) Code, and the LSA Code. The IMO also publishes guidance on safety issues. The International Labour Organization maintains the Maritime Labour Convention (MLC), 2006, which provides standards for regulating working conditions for seafarers.

The ISM Code was adopted by the IMO in 1993 and entered into force in 1998. It provides an international standard for the safe and reliable operation of a vessel and its equipment, and for compliance with all the applicable regulations and requirements. The ISM Code is the basis for SOLAS requirements for an SMS,International Maritime Organization, International Convention for the Safety of Life at Sea (SOLAS), 1974 (as amended December 2000), Chapter IX, Regulation 3. which is required for all cargo vessels larger than 500 GT engaged in international voyages outside the Great Lakes. An SMS involves individuals at all levels of an organization and promotes a systematic approach to hazard identification, risk assessment, and risk mitigation. Requirements under the ISM Code include the development of procedures for shipboard operations and emergency preparedness, and documentation of the vessel’s maintenance.International Maritime Organization, International Management Code for the Safe Operation of Ships and for Pollution Prevention (International Safety Management [ISM] Code), 1993 (as amended 2013), paragraphs 1.4 and 10.2. The ISM Code also requires that a company’s SMS provides procedures for seafarers to report accidents and non-conformities.Ibid, paragraph 1.4.4.

1.10.1 Safety culture

Safety culture is the way that safety is perceived, valued, prioritized, and managed throughout all levels of an organization. It encompasses the attitudes, beliefs, perceptions, and values of all members of the organization in relation to safety, and is underpinned by trust and open communication.

A safety culture may be described in terms of its level of maturity. Levels of maturity are defined by such factors as how reactive (or proactive) an organization is to safety risks, how regulatory compliance and organizational performance measurements are viewed, how communication occurs within and across hierarchies, and how individuals in the organization perceive their roles in ensuring safety. More specifically, in a “just culture,” members of an organization feel safe reporting safety issues before harm occurs and this is viewed as a positive contribution. In contrast, in a “blame culture,” there may be a fear of repercussion and skepticism regarding protection from repercussion; a lack of communication from management to the crew in response to reported risks; or no reward process for reporting.P. Hudson, “Safety Culture – Theory and Practice,” in: North Atlantic Treaty Organization, Research and Technology Organization document RTO-MP-032 (2001), The Human Factor in System Reliability: Is Human Performance Predictable?, at https://apps.dtic.mil/sti/pdfs/ADA388027.pdf. (last accessed 21 October 2025). Recognizing this fear of repercussion, many organizations establish anonymous methods of reporting safety concerns.

One purpose of the ISM Code is to support and monitor the development of effective safety cultures in maritime organizations. In a 2024 IMO report on the effectiveness and effective implementation of the ISM Code, it was found that a “blame culture” is prevalent¾that is, that seafarers are reluctant to report hazards, non-conformities, near misses, and incidents because of fear of being blamed and punished. With respect to the reluctance to report, the report states that

[t]his is a significant area of concern, as a key requirement for the success of the ISM Code is good communication and reporting between ship-based crew and shore-based management. These factors clearly impact the ISM Code's ability to instil a safety culture.International Maritime Organization, MSC 109/INF.3, Study on the effective implementation of the International Safety Management (ISM) Code (23 September 2024), p. 84.

InterManager, the association for ship management companies,Columbia Shipmanagement Ltd. has been a full member of InterManager since 1993. also identifies 2-way communication as a priority (“We learn from those who do the job”), and recognizes the importance of trust in developing an effective safety culture.InterManager, General Principles of Conduct and Action, available at https://www.intermanager.org/intermanager-general-principles-of-conduct-action-final/ (last accessed 21 October 2025), pp. 40 and 51.

Columbia Group is the parent company of Columbia Shipmanagement Ltd. Its code of conduct, dated December 2022, emphasizes “walking the walk” instead of “talking the talk” and provides guidance highlighting honest and transparent communications and ethical behaviour. The code of conduct details multiple ways to report any practices that contradict or are suspected to contradict any rules, regulations or Columbia Shipmanagement Ltd. policies, including a toll-free number and email address for a dedicated third party that assures anonymity.

Contemporary safety science acknowledges that an effective safety culture requires more than regulatory compliance.T. Nævestad, I.S. Hesjevoll, and R. Elvik. “How can regulatory authorities improve safety in organizations by influencing safety culture? A conceptual model of the relationships and a discussion of implications.” Accident Analysis and Prevention (2021), p. 159. Because shipping operations have varying levels of complexity in size, personnel, vessel age, engineering of vessels, and routes, risks across the shipping industry will vary greatly. Regulations prescribe a minimum level of safety for a broad range of vessels and conditions. However, they do not identify or mitigate all hazards that may be present. In the maritime industry,For 2 recent examples from the fishing industry, see marine transportation safety investigation reports M21A0065 and M20P0229. regulatory compliance is often perceived as safety compliance. Regulatory compliance does not guarantee safe operations, because risks in an organization that is compliant with regulations may be underestimated.

On 16 June 2000, 2 passengers drowned after the small passenger vessel True North II sank. Following the occurrence, the Board issued a recommendation to Transport Canada (TC) concerning safe practices and conditions beyond regulatory compliance.TSB Recommendation M01-02. This recommendation shows a long-standing TSB awareness of the importance of the safety culture as distinct from regulatory compliance in the Canadian maritime industry.

1.10.1.1 Safety procedures and successful communication

Procedures contribute to safety when they have these characteristics:

- They are specific to the operations that they apply to.

- They take into account activities, hazards, and operating conditions.

- Their intended audience can find, understand, and use the information in them.International Organization for Standardization, ISO 24495-1:2023, Plain language – Part 1: Governing principles and guidelines (2023).

Developing and maintaining procedures requires an understanding of and experience with the context, goals, risks, and activities of the operations. Note that part of the context is the domain expertise that those performing the procedures bring to their work; this domain expertise comes from formal training and certification and from experience.

Procedures should be reviewed regularly to ensure that they still reflect the activities and operating conditions they apply to and that they are being used effectively. Reviews may result in a return to documented procedures or an update to the procedures. For procedure reviews, communication between the vessel crews and the shore staff is essential. Crew members should know that their input is needed, be aware of the ways to provide information, and be confident that they can provide such information without risk. From the other side, shore staff should know what kinds and amounts of information to expect and how to manage its inclusion in the SMS. They should also be prepared to follow up if the information is not provided or if changes are needed.

In this occurrence, the safety and workload pressures were quite different for the crew, who dealt with the immediate hazards, and the technical shore staff, who maintained the SMS procedures. The crew were attempting to balance their personal workload and safety under operational pressure to perform their tasks. The technical shore staff were managing fleets of ships instead of individual tasks and were focused on efficient ship movements and avoiding delays.

1.10.1.2 Paper safety

The Field Guide to Understanding ‘Human Error’ discusses the concept of “fantasy documents.”S. Dekker, The Field Guide to Understanding ‘Human Error’, 3rd Edition (Ashgate Publishing, 2014), p.149. These are documents created by an organization for safety purposes, but produced by safety departments that are at a distance from the actual operations. This results in safety management documentation that no longer reflects the actual safety risks present in day-to-day activities. When the safety documentation diverges from managing actual safety risks in such a manner, an organization may be described as having a culture of “paper safety.”In the nuclear industry, the military, and other high-risk sectors, a culture of paper safety is described as one focused on compliance and opposed to real safety. For a description in 1 important occurrence, see The Nimrod Review: An independent review into the broader issues surrounding the loss of the RAF Nimrod MR2 Aircraft XV230 in Afghanistan in 2006, by C. Haddon-Cave QC (28 October 2009).

1.10.1.3 Authority gradients

Authority gradient refers to the decision-making hierarchy between those with higher perceived authority (for example, the master of a vessel) and those with lower perceived authority (for example, a member of the crew). This gradient is characterized by several factors, including each person’s experience and their position on the vessel. A strong authority gradient may be a barrier to the decision-making dynamics of a crew. This is because a crew member may feel uncomfortable expressing disagreement with more senior crew members. This in turn reduces communication and increases the probability that a more junior crew member will not speak up about a safety risk.B. Luva and A. Naweed. “Authority gradients between team workers in the rail environment: a critical research gap,” Theoretical Issues in Ergonomics Science, Vol. 23, Issue 2 (2022). In some contexts, there can be more than 1 authority gradient. For example, deck and engine crew may effectively function as 2 separate hierarchies. Hierarchies can also connect to each other, although connections may be limited. For example, a shore-based superintendent connects to the master of the vessel and technical superintendents communicate with the chief engineer for technical matters.

1.10.2 Regulatory compliance

Regulatory compliance is verified externally through audits and inspections by port states, flag states, and classification societies, as well as through insurance inspections and technical inspections by equipment service personnel. Routine audits and inspections are snapshots by nature, and because they are relatively short, are not expected to be exhaustive. Additional inspections that follow an accident or near miss are more comprehensive. Regulatory compliance is also monitored and verified internally by shore staff and by crew on the vessel.

1.10.2.1 International Safety Management Code certification and inspection

As a record of compliance with the ISM Code, the operating company is first issued a document of compliance (DOC) once the company’s processes have passed audit by an accredited organization. Next, the company’s vessel is issued a safety management certificate (SMC). When there is a change such as a new management company, interim certificates with a maximum validity of 6 months are issued.International Maritime Organization, International Management Code for the Safe Operation of Ships and for Pollution Prevention (International Safety Management (ISM) Code), 1993 (as amended 2013), Part 14, paragraphs 14.1-2. The certificates are “interim” to allow for the new operator to become familiar with the vessel and implement any needed measures for compliance with the ISM Code. For example, it took 4 months for the new operator to identify the hydraulic leak on the lifeboat davit cylinder in maintenance records. At the time of the occurrence, Columbia Shipmanagement Ltd. held an interim DOC, issued by DNV, because the Golden Zhejiang was the first bulk carrier in its fleet flagged in Hong Kong. Additionally, the vessel held an interim SMC, issued by the American Bureau of Shipping. The interim certificates were issued following audits on 06 May 2023. As is usual with an audit for an interim certificate no non-conformities were noted and no observations were made when these certificates were issued.

In response to the occurrence, an additional ISM audit of the Golden Zhejiang was completed on 24 September 2023 by the American Bureau of Shipping. The audit identified

- a Non-Conformity/Downgraded Major Non-Conformity related to training: “The Company should establish and maintain procedures for identifying any training that may be required in support of the SMS and ensure that such training is provided for all personnel concerned;”American Bureau of Shipping, ISM Audit, 24 September 2023. and

- a Non-Conformity/ Downgraded Major Non-Conformity stating that the vessel was “not being maintained in accordance with requirements.”Ibid.

Approximately 47 deficiencies supported the non-conformity related to maintenance, indicating that “the ship is considered as seriously lacking maintenance.”Ibid.

The deficiencies identified included items related to hatches, coamings, self-closing fire doors, pumps, and lights. The nature of the deficiencies, which included corrosion and wastage, indicates that it is likely that the deficiencies were present before the interim certificates were issued. However, the audit also noted that no deficiencies were recorded in the vessel’s planned maintenance system.

1.10.2.2 Maritime Labour Convention 2006 certification and inspection

The MLC 2006 defines standards for health and safety protection and accident prevention. The MLC 2006 requires flag states to adopt, effectively implement, and promote occupational health and safety policies and programs on ships that fly their flag.

At the time of the occurrence, the Golden Zhejiang held an interim MLC certificate. The MLC inspection was carried out by the vessel’s classification society, American Bureau of Shipping (ABS), on behalf of the Hong Kong flag administration at the same time as the ISM audit (06 May 2023). The assessment remarks on the inspection report indicated that a “Walk about the vessel was carried out during the inspection, no obvious defect was found.”American Bureau of Shipping, MLC Report, 06 May 2023.

1.10.3 The Columbia Shipmanagement Limited safety management system

The Columbia Shipmanagement Ltd. SMS was documented in a number of manuals, which totalled over 1000 pages:Reading speed depends on the individual and the type of content. For an average reader. 1000 pages of general content might take 24 hours of reading (30-40 pages per hour). Reading speeds are likely to decrease if the content is technical or in a language other than the reader’s first language, reading conditions are poor, and so on. (M. Brysbaert, “How many words do we read per minute? A review and meta-analysis of reading rate,” Journal of Memory and Language, Vol. 109 [December 2019]).

- The General Operations Manual: Quality, Safety & Health, Environmental & Energy Management System contained policies and procedures related to these areas.

- The Cargo Operations Manual: Dry Cargo contained detailed information about maintaining hatch covers and coamings.

- The Training Manual for Cargo Ships provided information in general about life-saving appliances.

These manuals were generalized for cargo ship requirements and were managed as controlled documents. Procedures were not specific to the Golden Zhejiang or to the equipment; some procedures pointed to manufacturer documentation, such as the lifeboat manual, for specific information. Furthermore, policies and procedures had been updated to include references to IMO circulars and similar guidance. As a result, to use the procedures, crew needed to combine over 1000 pages of SMS procedures with separate manufacturer documentation and interpret the combination.See also Marine Transportation Safety Investigation M22A0332. In this investigation, the TSB made a finding about the interpretation of procedures and the lack of communication between the operational level (crew) and management.

To manage shipboard maintenance, the company used planned maintenance system software to document defects, order parts, and track planned maintenance, such as the free-fall lifeboat safety checks. The investigation determined that the planned maintenance system was on board the Golden Zhejiang at the time of the occurrence, but was not being consistently used. The crew used the planned maintenance system to determine when safety checks were due, such as the SOLAS visual inspection of the lifeboat, and to record when they were done. The planned maintenance system referenced inspection requirements set out in other documents, such as the checklist required by regulation 36.1. However, it did not document details about what was required for the safety check nor what was done during the safety check when it was signed off. As well, the planned maintenance system was not being used to record defects. At the time of the occurrence, the planned maintenance system task for the monthly safety check was as follows:

SF00050-IMO INSPECTION OF LIFEBOAT EQUIPMENT

========================

Interval: Monthly By: Crew

Applicable to: All vessel types

SOLAS III/20.7.2

7.2 Inspection of the life-saving appliances, including lifeboat equipment, shall be carried out monthly using the checklist required by regulation 36.1 to ensure that they are complete and in good order. A report of the inspection shall be entered in the log-book.

CSM NOTES:

Print the checklist from the Work Instruction and fill it up for each LSA equipment as appropriate. Any discrepancies to be reported in the history report.Columbia Shipmanagement Ltd., internal document.

1.10.3.1 Safe working practices

A safe working practice before the start of a procedure is to carry out a pre-job assessment. This assessment, sometimes called a toolbox talk, is a brief meeting of all those involved to discuss the procedure, the hazards and risks involved, and the existing defences. The meeting provides an opportunity for crew members, especially new crew members, to identify and mitigate hazards. If identified hazards are mitigated, then work can begin or continue. However, if identified hazards cannot be readily mitigated, then the work must be put on hold.

The Columbia Shipmanagement Ltd. General Operations Manual contained procedures and descriptions to support these practices:

- A procedure that outlines both daily work planning meetings and toolbox talks.

- A detailed risk management procedure that applies to all company employees, including examples of when a risk assessment should be conducted (routine activities requiring work permits, non-routine or unplanned tasks, and changes to key personnel).

- A detailed description of the work permit system, which includes 14 different types of permits for specific tasks, such as work in enclosed spaces, as well as a generalized work permit to be used for other tasks. According to the description, a risk assessment is to be conducted, personnel performing the work are to be trained and competent to complete the work, personal protective equipment (PPE) is to be available, and sources of stored energy (including the potential energy due to the height of the lifeboat) are to be isolated on any equipment that would be worked on. The need for a work permit is to be identified during the daily work planning meeting.

- The work permit system also includes lock-out/tag-out requirements where appropriate.

The General Operations Manual stated that enclosed lifeboats may be considered as an enclosed space, for which specific procedures and permits apply. The Training Manual for Cargo Ships contained a lifeboat section which stated that weekly and monthly checks are required for lifeboats. At a number of points, the SMS manuals directed crew members to refer to manufacturer’s instructions.

The following documents and manuals contained various levels of information on weekly and monthly lifeboat checks:

- General Operations Manual – Included training and drill frequency for free-fall lifeboat drills and launches, covered the maintenance program for lifeboats by directing users to the planned maintenance system, and contained a “Safety Officer’s Checklist” for the purpose of Port State Control inspection readiness. This checklist included lifeboat and release system checks to be completed monthly.

- Training Manual – Described general requirements for weekly and monthly safety checks. Referred reader to manufacturer’s instructions for information, operation, and procedures.

- Norsafe Operation and Maintenance Manual for the lifeboat (2008 version) – Provided detailed instructions for weekly and monthly maintenance and safety checks by crew and inspections by service technicians. This version of the manual was available on board. It contained instructions for resetting the release mechanism after a drill or release, and it specified detailed weekly and monthly maintenance tasks for the crew to complete (see Appendix A). The manual also contained a monthly checklist that included a check of the release mechanism (among other things, verification that the release hook was engaged, the release safety pin and safety lever were in place, and the release wheel had been turned to return slack to the cable). As well, the monthly checklist specified that the rudder should be pointing straight.

- Viking-Norsafe Operation and Maintenance Manual (2020) – Provided detailed instructions for weekly and monthly maintenance and safety checks. This version of the manual was not available on board the vessel.

In this occurrence, the lifeboat was stored 19 m above the water. According to the SMS, this is high enough that the potential energy could be considered a source of energy that should be locked out. The SMS was unclear about whether the free-fall lifeboat, as an enclosed lifeboat, should be considered an enclosed space.

On the morning of the occurrence, the chief engineer’s “work planning meeting,” held per the SMS, was the first opportunity to discuss work permits and risk assessments for entry into the lifeboat. During the meeting, the participants did not identify any requirement for a work permit or lock-out. During the lifeboat safety check, the issue with the steering was not treated as a separate task from the ongoing check and no additional meeting between the second and fourth engineer to identify hazards took place.

1.10.3.2 Safety equipment familiarization

During familiarization, the specifics of a vessel and its equipment are introduced to supplement the existing knowledge, skills, and experience of incoming crew members. Familiarization requirementsInternational Maritime Organization, International Management Code for the Safe Operation of Ships and for Pollution Prevention (International Safety Management (ISM) Code), 1993 (as amended 2013), section 6.3 and International Maritime Organization, International Convention for the Safety of Life at Sea (SOLAS), 1974 (as amended December 2000), Chapter VI, Regulation 1. with regards to emergency equipment are related to their use in an emergency, but a good understanding of equipment is also important for safe maintenance. Safety familiarization requirements for crew members joining a vessel were documented in the General Operations Manual. Part 1 of the safety familiarization checklist covered the location of lifeboats and how to safely enter the lifeboat, go to the allocated seating position, and fasten the safety harness. Part 2 covered how to launch the lifeboat.

The investigation reviewed the safety training records for the crew on board the Golden Zhejiang at the time of the occurrence. There were 3 different versions of the Columbia Shipmanagement Ltd. safety familiarization checklist used for the 22 crew members. One version of the checklist (dated 10 August 2022) stated that familiarization for the master, chief officer, chief engineer, and second engineer should be done during handovers. A 2nd version of the checklist (dated 30 March 2023) included only Part 1, and stated that all seafarers were to complete familiarization within 24 hours of joining the vessel. A 3rd version of the checklist (dated 26 July 2023) also stated that Part 2 was to be completed within 14 days. SOLAS regulations (Chapter III, Regulation 19) require familiarization to be complete within 14 days.

Columbia Shipmanagement Ltd. used drills as an opportunity for familiarizing crew members with the lifeboat operation, including the release mechanism. On the Golden Zhejiang, lifeboat drills had not yet been conducted because of a hydraulic leak in the davit. The investigation found no record of lifeboat familiarization for the second engineer in either the safety training records or the second engineer’s handover report, dated 23 August 2023.

The second engineer had been on board for less than 14 days and had not yet completed the required familiarization. IMO guidelinesInternational Maritime Organization, MSC/Circ. 1206/Rev.1, Measures to Prevent Accidents with Lifeboats (11 June 2009), section 2.3.3. recommend that personnel who conduct checks, inspections, maintenance, or adjustments of lifeboats should be trained or fully familiar with the lifeboat, launching appliances, and associated equipment.

An earlier TSB investigation, into the grounding of the tanker Halit Bay, found that the absence of familiarization can lead to the lack of knowledge required to operate equipment proficiently.Marine Investigation Report M14C0045.

1.10.3.3 Reporting safety concerns

The Columbia Shipmanagement Ltd. General Operations Manual describes near miss reporting, and the reporting of hazards and safety concerns, as “a natural part of a well-developed safety culture […] based on trust.”Columbia Shipmanagement Ltd., 04.6 “Near Miss Reporting and Investigation,” Quality, Safety and Health, Environmental and Energy Management System: General Operations Manual (version updated 07 September 2023). The manual described multiple avenues for reporting safety concerns:

- Open reporting system. Anonymous reporting to a third-party company that serves the Columbia Group is allowed, where the report is about any contradiction of rules, regulations, or company policies. This option is not available to crew for reporting safety concerns such as hazards or near misses.

- Near miss reporting and investigation procedures. Crew members can either report unsafe acts or conditions verbally to the head of a department or fill out a Safety Observation Note, which is placed in a collection box and collected by the chief officer. The master is responsible for transferring the information into a near miss reporting form and sending it to the office. The SMS suggests that these notes may be completed anonymously. However, crews on a vessel are typically too small for anonymity in such a process.

- Procedure to request changes to controlled documentation. A crew member can request a change to the SMS documents by informing the master and discussing their concerns.

That is, as is typical, many of the ways for crew to communicate with the shore staff about safety risks went through the master. The investigation found no records of safety concerns about the lifeboat, the lifeboat davit, and the lifeboat securing arrangements being reported.

According to the SMS, the safety officer was expected to hold health, safety, environment, and energy efficiency meetings with the crew at least once a month, with minutes produced by the safety officer and circulated amongst the crew, emailed to the company, and posted on the notice board.

1.10.3.4 Reporting requirements for defects and incidents

The General Operations Manual defined defects as “any mechanical malfunction or equipment failure, that cannot be rectified with the existing resources onboard and which could either directly or indirectly lead to an adverse impact to safety...”Columbia Shipmanagement Ltd., 09.8 “Handling Defects,” Quality, Safety and Health, Environmental and Energy Management System: General Operations Manual (version updated 07 September 2023). Defects must be reported in the planned maintenance system.

In the case of the Golden Zhejiang, a hydraulic leak on the free-fall lifeboat davit had existed from the time the vessel was transferred to the new management company, and it had prevented the crew from performing the free-fall lifeboat drills. This defect had been noted on the monthly safety checks since June 2023, but it had not been reported in the planned maintenance system.

The General Operations Manual stated that incidents (accidents or near misses) must be reported within 24 hours and must be investigated, with a focus on root causes and actions to prevent recurrence.

As required by the SMS, the lifeboat accident was reported immediately. The initial report, issued on the same day as the occurrence, stated that the second engineer had “by mistake moved Emergency release handle instead of emergency steering handle” and concluded that the probable cause was “Lack of knowledge and safety awareness of crew members working in the lifeboat. Before entering, Lifeboat should be properly secured.”Columbia Shipmanagement Ltd., Incident report (02 September 2023).

A safety meeting was held on the day after the occurrence, on 03 September 2023. At this meeting, a marine superintendent spoke to the entire crew. He reminded the crew generally of the importance of safety familiarization, following procedures, using checklists, being familiar with equipment instructions, and asking an officer if in doubt. On 07 September, Columbia Shipmanagement Ltd. repeated the familiarization (Parts 1 and 2) on the free-fall lifeboats for all crew of the Golden Zhejiang. The health and safety meeting record form includes sections for comments about a monthly review of the SMS. During the health and safety meeting on 08 September, no comments were noted related to improvements for the SMS and no follow-up actions were taken.

The incident investigation and follow-up were conducted by 3 members of the shore staff. The final accident investigation report was completed on 12 October 2023 and approved on 25 October 2023. This final report contained the same conclusions as the initial report, holding the second engineer responsible:

The Second engineer joined the vessel 12 days prior to incident, and this was his first maintenance task for this particular FFLB. The task obviously looked simple to him and apparently, he didn’t consider to study the poster provided in the lifeboat which describes the operation of the release system.Columbia Shipmanagement Ltd., Incident investigation report (12 October 2023).

1.11 Previous occurrences

Since 1996, the TSB has investigated 7 accidents involving inadvertent lifeboat releases on commercial vessels, all of which involved serious injuries.Marine transportation safety investigation reports M20P0353, M17A0391, M06L0063, M02L0061, M96L0043, M93L0006, and M00W0265. The most recent involved a free-fall lifeboat:

- M20P0353 (Blue Bosporus)—On 01 December 2020, the crew on the bulk carrier Blue Bosporus were carrying out a free‑fall lifeboat drill while at anchor in English Bay, British Columbia, when the wire rope slings holding the lifeboat failed and it fell approximately 14 m to the water. The 2 crew members in the lifeboat were seriously injured. In this occurrence, the securing mechanism intended to hold the lifeboat in place during the drill failed. The slings were not certified. In the report, the TSB found that

In the absence of any international guidance requiring free-fall lifeboat slings to be verified periodically, inspected before use, and marked with a safe working load, there is a risk that this critical equipment will be overlooked during inspections or its safe limits will be exceeded, leading to an accident. Data on all marine transportation occurrences since 1995 are available on the TSB website at https://www.tsb.gc.ca/eng/stats/marine/data-6.html. This information is updated monthly.

1.12 TSB laboratory reports

The cables used to secure the lifeboat to the launching structure were sent to the TSB laboratory for further examination.

The TSB completed the following laboratory reports in support of this investigation:

- LP038/2024–Photo Analysis

- LP170/2023–Lifeboat Restraints Examination

1.13 TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

Safety management is a Watchlist 2025 issue. As this occurrence demonstrates, the presence of formal safety management processes does not ensure that hazards are identified and that an effective, mature safety culture is being developed.

2.0 Analysis

The Golden Zhejiang’s free-fall lifeboat, with 1 person inside, fell during a weekly safety check after the lifeboat was inadvertently released and the cables that were used to secure the lifeboat to the launching structure failed. The analysis will focus on the lifeboat safety checks, the level of familiarity with the lifeboat, the information needed to perform lifeboat checks safely, and the supporting safety management processes. The analysis will also examine the relationship between organizational safety culture and communication, and how these are represented in safety management systems (SMSs) in maritime operations.

2.1 Lifeboat safety checks

The maritime community has recognized that there are many hazards associated with operating and maintaining lifeboats. Safety of Life at Sea (SOLAS) regulations define requirements for lifeboat safety checks and inspections. The International Maritime Organization (IMO) provides additional guidance in the form of circulars. An SMS should incorporate this information and guidance in a way that is readily available to the crew and easily accessed. For example, this could involve reproducing the checklist found in regulation 36.1 in the planned maintenance system so the crew are not required to review multiple documents before performing their task.

According to the Columbia Shipmanagement Ltd. SMS and to the usual practice on board large commercial vessels, weekly safety checks on the Golden Zhejiang were divided between the deck and the engine room crew. The deck officers documented weekly safety checks in the planned maintenance system. However, the records only indicate that the safety checks were completed and do not include the level of detail as per the SOLAS regulations. The engine room crew’s safety check of the vessel’s lifeboat, documented in the engine room log, was part of a set of weekly checks of safety equipment. This lifeboat check required starting the engine and checking the lights and steering. The safety officer’s monthly safety checks, which were conducted in preparation for port state inspections, were more detailed and recorded a hydraulic leak on the davit, which was not documented in the planned maintenance system.

Lifeboat hazards and precautions are described in detail in the manufacturer’s lifeboat manual. As well, the Columbia Shipmanagement Ltd. General Operations Manual identified 2 hazardous characteristics of lifeboats that should require some form of risk assessment before work (stored energy because of the height above the water; the enclosed space of a lifeboat). There are additional risks associated with someone new to the vessel who had not completed a full familiarization conducting the weekly safety checks of the free-fall lifeboat – these are mentioned in IMO guidance.International Maritime Organization, MSC/Circ. 1206/Rev.1, Measures to Prevent Accidents with Lifeboats (11 June 2009). Additionally, the vessel SMS recommended that a risk assessment take place after a change of key personnel. However, no risk assessment was carried out and the risks went unmitigated. Consequently, the fourth engineer and second engineer were not reminded of the risks before they conducted weekly safety checks, including on the day of the occurrence. Therefore, they entered the lifeboat without first assessing whether it was safe to do so.

Finding as to causes and contributing factors

The Golden Zhejiang’s SMS did not explicitly require a risk assessment before entering the free-fall lifeboat to conduct a safety check. Consequently, the fourth engineer and the second engineer began the weekly safety check without assessing the risks of the boat inadvertently being released.

2.2 Lifeboat release and fall

In the short interval between the time when the second engineer stepped out of sight of the fourth engineer and when the lifeboat fell, there is no record of the second engineer’s actions; because of his injuries, he has limited memory of the occurrence or of his time on the Golden Zhejiang.

Although the company determined that the second engineer did not read the signage inside the lifeboat and mistook the emergency release wheel for a steering mechanism, the TSB investigation was unable to determine how the lifeboat was released. The emergency steering was a standard type with which the second engineer was familiar. Additionally, a second steering wheel is not typically found in lifeboats. As a result, given his experience with emergency steering arrangements, it is highly unlikely that he operated the release wheel thinking it was connected to the lifeboat steering mechanism. IMO guidance identifies similarities between the lifeboat steering wheel and the release wheel as a risk, and it points out the need for clear signage. However, this guidance is about equipment whose primary purpose is for use under emergency conditions, when operators are likely to be under stress. Although the signage may not have been adequate to support use of the release mechanism in an emergency, it was sufficiently visible to a person standing beside or at the release station to make it clear the control was not for emergency steering.

The lifeboat manual gave detailed instructions for ensuring that the release mechanism was reset after a drill or other release; this requires resetting the safety lever, inserting the safety pin, and adding slack back into the cable by turning the release wheel 2 times clockwise. The manual also specified that the rudder should be in a straight-ahead position after each monthly safety check. As well, regulations require crew to ensure that all components of the release mechanism are properly and completely reset. The SMS and planned maintenance system on the Golden Zhejiang did not directly incorporate these details into the vessel’s checklists or processes, and the 2020 manual for the lifeboat was not on board the vessel for reference by the crew.

The investigation could not confirm that the safety pin and safety lever had been reset following the last documented release of the lifeboat in March 2023, nor that the release wheel had been turned back 2 full turns as described in the lifeboat manual. However, at least 1 other item from the monthly checklist in the lifeboat manual was not checked; during the safety check, the fourth engineer observed that the steering rudder was set hard to port although the monthly checklist specified that the rudder should be pointing straight. Additionally, weekly safety checks recorded in the planned maintenance system did not point to the correct SOLAS requirements for the lifeboat safety checks. Consequently, it is unclear exactly what was checked during the weekly safety checks.